Understanding the Versatile Nature of Silicone Tubing in Modern Applications

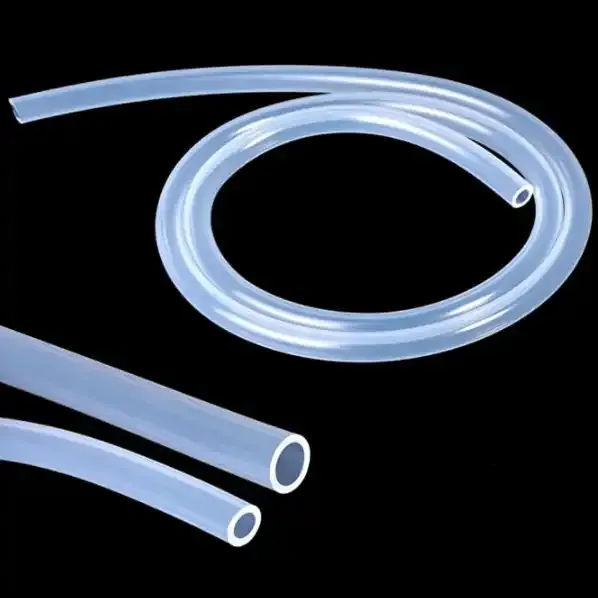

Silicone tubes represent one of the most versatile and widely-used components across numerous industries today. These flexible, durable conduits are engineered from high-quality silicone rubber, offering exceptional resistance to temperature extremes, chemicals, and environmental factors. Their unique properties make them indispensable in applications ranging from medical devices to industrial processes.

The remarkable adaptability of silicone tubes stems from their unique molecular structure, which combines organic and inorganic elements to create a material that maintains its integrity under diverse conditions. This fundamental characteristic has led to their widespread adoption across multiple sectors, where reliability and performance are paramount.

Key Properties and Characteristics of Silicone Tubing

Temperature Resistance and Durability

One of the most notable features of silicone tubes is their exceptional temperature resistance. These tubes can withstand temperatures ranging from -60°C to +230°C without losing their structural integrity or essential properties. This remarkable temperature range makes them ideal for applications involving extreme heat or cold, such as automotive engine components or laboratory equipment.

Beyond temperature resistance, silicone tubes demonstrate outstanding durability against wear and tear. They maintain their flexibility and strength even after prolonged use, resisting compression set and retaining their original shape. This longevity translates to reduced maintenance requirements and lower replacement costs over time.

Chemical Compatibility and Safety Features

Silicone tubing exhibits excellent resistance to various chemicals, oils, and solvents. This chemical inertness ensures that the tubes won't react with or be degraded by most substances flowing through them. Additionally, they don't leach harmful chemicals or affect the purity of materials they transport, making them particularly valuable in pharmaceutical and food processing applications.

From a safety perspective, silicone tubes meet stringent regulatory requirements, including FDA and USP Class VI standards. They're non-toxic, non-pyrogenic, and can be sterilized using various methods, including autoclave, gamma radiation, and ethylene oxide treatment.

Industrial Applications and Uses

Manufacturing and Processing Industries

In manufacturing settings, silicone tubes play crucial roles in fluid transfer, pneumatic systems, and process control applications. Their ability to handle high-pressure environments while maintaining flexibility makes them ideal for peristaltic pumps and fluid transfer systems. Industries such as chemical processing, food and beverage production, and pharmaceutical manufacturing rely heavily on silicone tubing for their operations.

The automotive sector particularly benefits from silicone tubes in various applications, including coolant lines, fuel system components, and air handling systems. Their resistance to engine heat and automotive fluids ensures reliable performance under demanding conditions.

Medical and Laboratory Applications

The medical industry represents one of the largest users of silicone tubing. From surgical instruments to dialysis machines, these tubes are essential components in numerous medical devices. Their biocompatibility and ability to be sterilized make them perfect for applications where patient safety is paramount.

In laboratory settings, silicone tubes are used extensively for fluid transfer, gas delivery, and various analytical processes. Their clarity allows for visual monitoring of fluid flow, while their chemical resistance ensures accurate and contamination-free results.

Selection and Maintenance Guidelines

Choosing the Right Specifications

Selecting appropriate silicone tubing requires careful consideration of several factors, including inner and outer diameter dimensions, wall thickness, and specific material grade. The intended application's pressure requirements, temperature range, and chemical exposure must all be evaluated to ensure optimal performance.

Working with reputable manufacturers or suppliers who can provide detailed technical specifications and material certifications is essential. This ensures that the selected silicone tube meets all necessary requirements and regulatory standards for its intended use.

Proper Care and Maintenance Practices

While silicone tubes are inherently durable, proper maintenance can significantly extend their service life. Regular inspection for signs of wear, proper cleaning procedures, and appropriate storage conditions are essential aspects of maintenance. For medical and laboratory applications, following prescribed sterilization protocols is crucial.

Implementing a regular maintenance schedule and documenting any issues or replacements helps maintain system integrity and ensures consistent performance. Training staff in proper handling and maintenance procedures can prevent damage and extend the life of silicone tubing installations.

Environmental Impact and Sustainability

Eco-friendly Aspects of Silicone Tubing

Silicone tubes offer several environmental advantages compared to alternative materials. Their longevity reduces the frequency of replacement, thereby minimizing waste. Additionally, silicone material is inert and doesn't release harmful chemicals into the environment during use or disposal.

Many manufacturers now focus on sustainable production methods and offer recycling programs for used silicone products. The energy efficiency of silicone tube production processes continues to improve, reducing the overall environmental impact of these essential components.

Future Developments and Innovations

Research and development in silicone tubing technology continues to advance, with new formulations offering enhanced properties and performance characteristics. Innovations in manufacturing processes are leading to more precise specifications and improved quality control.

The integration of smart technologies and monitoring systems with silicone tubing applications is an emerging trend, allowing for better process control and predictive maintenance in industrial settings.

Frequently Asked Questions

How long does silicone tubing typically last?

Under normal operating conditions and proper maintenance, silicone tubes can last anywhere from 5 to 10 years. However, the actual lifespan depends on factors such as usage intensity, environmental conditions, and the specific application requirements.

Can silicone tubes be used for food-grade applications?

Yes, specific grades of silicone tubing are FDA-approved and suitable for food-grade applications. These tubes meet strict regulatory requirements and are commonly used in food processing and beverage production industries.

What are the maximum pressure ratings for silicone tubes?

Pressure ratings vary depending on the tube's dimensions and specific grade, but standard silicone tubes typically handle pressures from 10 to 60 PSI. Specialized reinforced variants can withstand even higher pressures, up to several hundred PSI.

Are silicone tubes recyclable?

While silicone tubes can be recycled, the process requires specialized facilities. Many manufacturers offer take-back programs for used silicone products, ensuring proper recycling and reducing environmental impact.