silikongummier høj temperatur

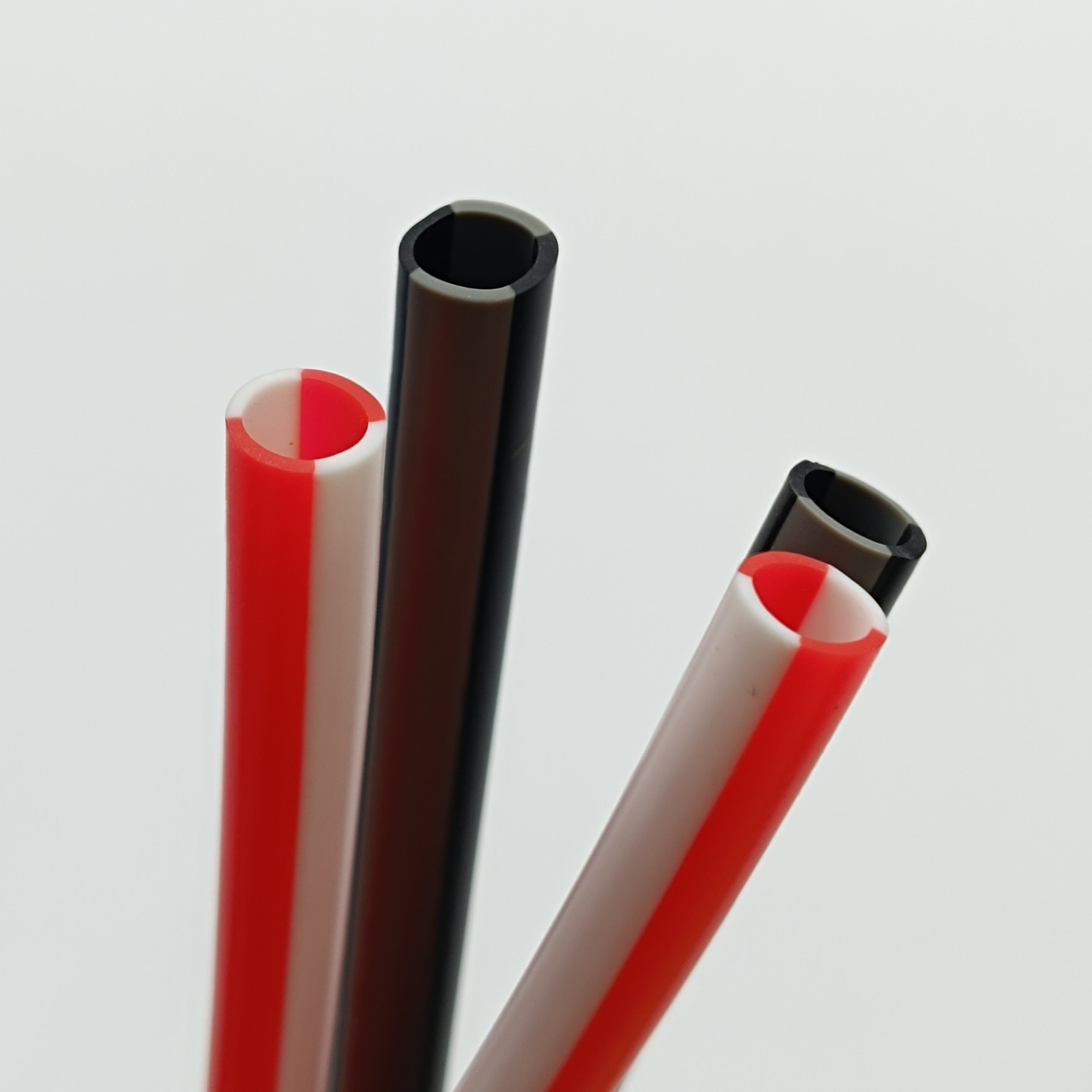

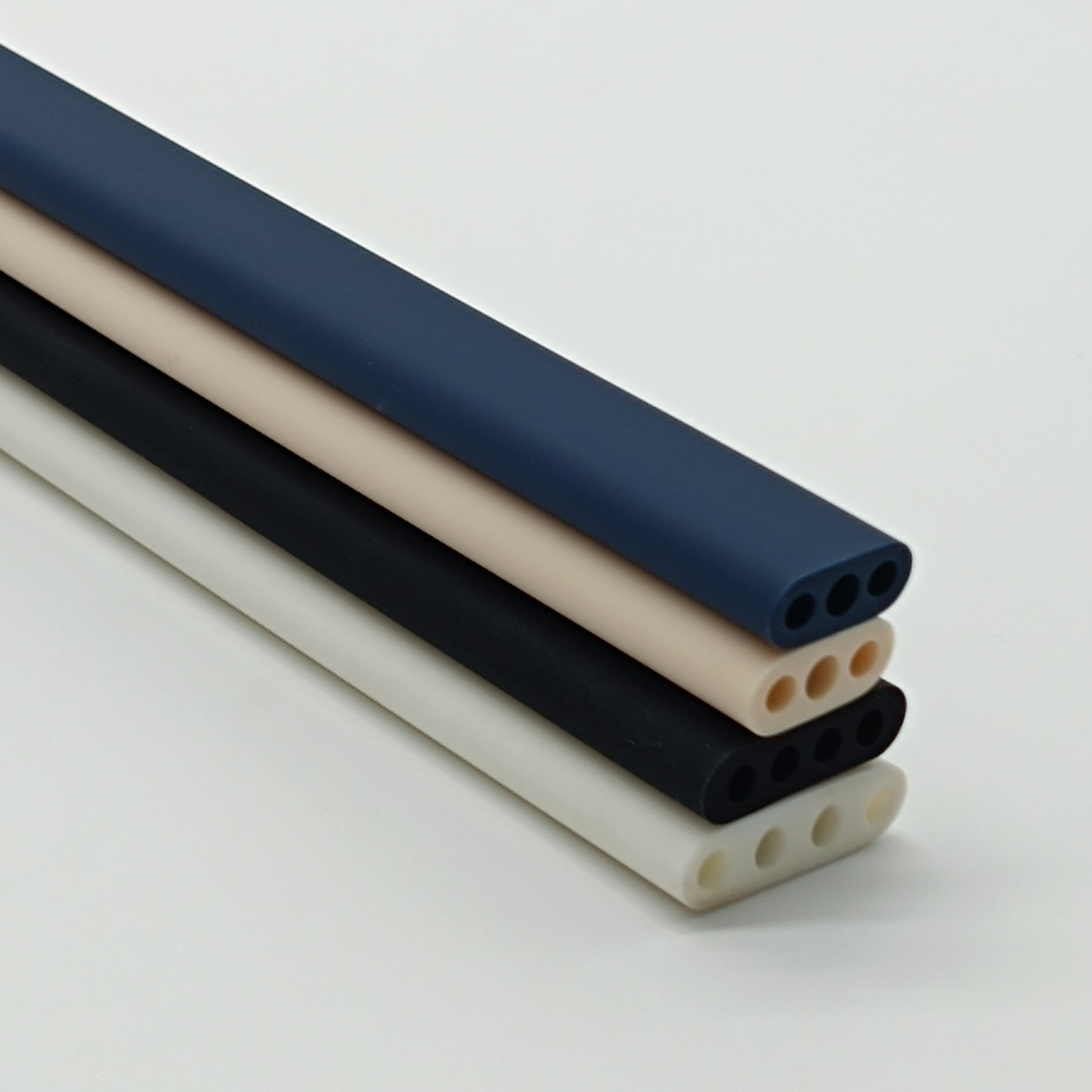

Silikongrommets til høj temperatur er specialfremstillede komponenter, der er konstrueret til at modstå ekstreme temperaturforhold, samtidig med at de sikrer pålidelig tætning og beskyttelse. Disse essentielle industrikomponenter fremstilles af silikomaterialer i høj kvalitet, som bevarer deres strukturelle integritet og ydeevneegenskaber ved temperaturer mellem -65°F og 450°F (-54°C til 232°C). Grommetsene har en unik molekylær struktur, som sikrer fremragende termisk stabilitet, kemikaliemodstand og holdbarhed under krævende forhold. Komponenterne udfører flere funktioner, herunder kabelhåndtering, vibrationsisolering samt beskyttelse mod fugt, støv og andre miljøpåvirkninger. Silikomaterialet med høj temperaturmodstand tilbyder overlegen fleksibilitet og modstandsdygtighed, hvilket gør det muligt for grommetsene at fastholde deres tætnings egenskaber selv under termiske cyklusforhold. Deres alsidige design gør dem ideelle til forskellige anvendelser inden for industrier såsom bilindustrien, luftfart, industrielle maskiner og elektronisk udstyrsproduktion. Grommetsene findes i flere størrelser, konfigurationer og hårdhedsgrader for at imødekomme forskellige installationskrav og ydelsesspecifikationer.