The Critical Role of Sealing in Industrial Applications

Fundamentals of Leak Prevention Technology

Leak prevention tech matters a lot in industrial environments because it keeps operations running smoothly and stops expensive problems from happening. At its core, good sealing works by making sure nothing escapes from where it shouldn't go. Industries rely on different types of seals depending on what they need. Static seals work great for stationary equipment, stopping leaks right at those fixed connections. Dynamic seals come into play when parts are moving around, which happens a lot in manufacturing plants. Nobody wants fluid dripping out while machines are running. The numbers tell an important story too. Back in 2020, American businesses lost roughly $51 billion across all sorts of systems simply because of leaks. That kind of money loss makes it clear why companies invest so heavily in better sealing solutions and leak detection technologies for their facilities.

Economic Impacts of Failed Sealing Systems

Failed sealing systems hit companies hard financially, usually causing expensive downtime plus safety issues. When these seals break down, companies deal with repair bills but also lose money from stopped operations and might even face lawsuits later on. Big companies report that leaks alone can cost them millions annually, so good sealing isn't just about keeping things running smoothly anymore it's actually about protecting the bottom line. Take oil refineries for instance, where faulty seals mean everything from halted production lines to massive spills that damage ecosystems and endanger workers. Real world incidents show what happens when seals fail they stop production cold, create environmental nightmares, and put people at risk. That's why smart businesses invest in quality sealing technology upfront instead of paying the price later through accidents, fines, or lost revenue from interrupted operations.

Material Properties Driving Silicone Gasket Performance

Extreme Temperature Resistance (-100°F to 500°F)

Silicone gaskets stand out because they can handle really big temperature swings without breaking down. We're talking anywhere between minus 100 degrees Fahrenheit all the way up to around 500 degrees F. What this means practically is that these gaskets keep working properly even when things get super hot or freezing cold, something that matters a lot in places like car engines and airplane components where temperatures fluctuate constantly. Parts in those industries face intense heat regularly, so staying stable becomes absolutely critical for avoiding breakdowns. Research into silicone properties shows pretty impressive results regarding how well it handles heat stress during tests. Compared to alternatives on the market today, most materials just don't cut it when pushed to similar temperature limits, often showing signs of wear or complete failure much sooner than expected.

Elastic Memory for Consistent Compression

Silicone gaskets have something called elastic memory, which basically means they remember their shape even after getting squished down. This matters a lot because when pressure changes happen all the time, like in factories running 24/7, the gaskets need to bounce back to work properly. Think about automotive assembly lines or food processing equipment that heats up and cools down repeatedly throughout shifts. These temperature swings put real stress on sealing components. According to field reports from maintenance teams across various industries, gaskets made with silicone tend to last longer between replacements compared to other materials. They just don't lose their grip as quickly, so there are fewer headaches with unexpected leaks disrupting production schedules.

Chemical Inertness Against Corrosive Substances

Silicone's chemical inertness is why so many manufacturers turn to it for gaskets in tough industrial settings where they're constantly battling harsh and corrosive substances. Unlike rubber or other common materials, silicone doesn't react with most chemicals, which explains why we see them all over chemical plants and food processing facilities. Take the pharmaceutical industry as one example silicon gaskets have stood up to aggressive solvents that would eat through cheaper alternatives within days. The fact that these gaskets last longer without breaking down means less downtime and fewer replacements, something plant managers appreciate when budgets are tight. That's probably why everything from semiconductor fabrication to dairy processing relies on silicone seals despite their higher initial cost.

Key Sealing Advantages of Silicone Gaskets

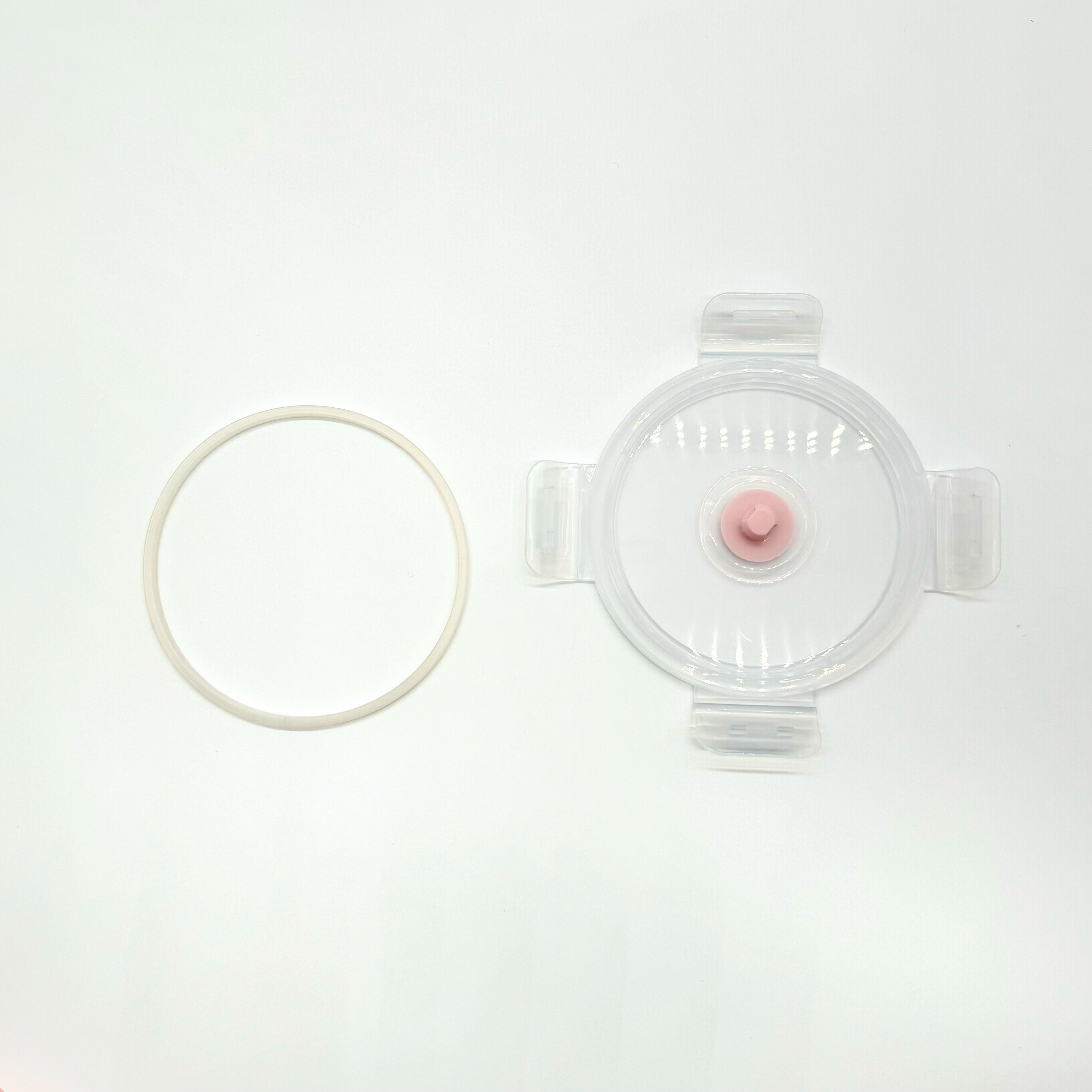

Adaptive Sealing on Non-Uniform Surfaces

Silicone gaskets have a real advantage when it comes to adapting to uneven surfaces, which helps create dependable seals even when things get tough. This makes them especially valuable in places like car manufacturing and aircraft assembly, where parts don't always fit perfectly together and tend to vibrate or move around during operation. What sets silicone apart is its remarkable flexibility that lets these gaskets hold up over time without breaking down or letting air escape, so there's less chance of leaks happening and better overall performance from the equipment. Studies show that switching to silicone gaskets cuts down on leakage problems in areas with tricky surface shapes, and this translates into smoother operations day after day.

Decades-Long Durability in Harsh Environments

Silicone gaskets really stand out when it comes to lasting power in tough environments, sometimes going decades before needing to be replaced at all. Many companies in different industries report this kind of performance, especially after putting them through their paces in some pretty brutal conditions. What this means practically is fewer times technicians have to check on them or swap them out, which saves money across years of operation. Lab tests actually show these gaskets keep working well even when pushed hard, making them a smart choice for situations where reliability matters most over the long haul.

UV/Ozone Resistance for Outdoor Applications

Silicone gaskets stand up really well against UV rays and ozone, which makes them great choices when materials are going to be outside where sunlight and air pollutants might break things down over time. Take telecom companies or solar panel installers for instance they depend on this property because their gear gets hammered by weather conditions all day long. Studies from material science labs show that these gaskets keep working properly even after months under harsh sun and polluted environments, so important components stay safe and functional. The fact that they last longer means equipment doesn't need replacing as often, which saves money on repairs and downtime something every business owner appreciates when managing field operations.

Industry-Specific Applications of Silicone Seals

Automotive Airbag and EV Battery Sealing

Silicone gaskets are pretty important for automotive safety systems, particularly airbags that need to inflate fast and seal properly during collisions to keep passengers safe. Good quality silicone gaskets make sure these life saving systems work right when they're supposed to. With electric vehicles becoming more common on roads today, there's growing interest in better sealing tech too. Manufacturers are looking at ways to maintain battery packs integrity while keeping everything running smoothly under different conditions. The auto industry wants materials that won't add unnecessary weight but still last long enough through regular wear and tear. Recent research shows cars equipped with proper silicone seals experience fewer problems caused by poor sealing, which means safer rides overall for everyone involved.

Aerospace Fuel System Protections

Silicone gaskets play a vital role in aircraft fuel systems by stopping leaks and keeping things safe during those long flights across different altitudes. The aerospace industry sets really strict rules for these components, so they need to meet some pretty amazing sealing requirements. We've seen this work time and again through all sorts of testing and official approvals that show silicone holds up under tough conditions. Take high altitude planes for instance, where maintaining proper pressure levels is absolutely essential. Traditional materials just don't cut it there because any leak could spell disaster. That's why manufacturers keep turning to silicone for its special characteristics that literally create a barrier against dangerous fuel escapes in flight.

Medical Device Sterilization Compatibility

Medical fields need sealing materials that work well with sterilization methods like autoclaving so they can keep medical equipment sterile. Silicone gaskets fit the bill because they handle high heat without breaking down, which makes them great choices for all sorts of medical uses. When manufacturers follow strict rules set by agencies like the FDA, it helps guarantee that these silicone gaskets will perform reliably and safely when keeping things sterile in different healthcare settings. Looking at real world cases and what experts say shows just how good silicone seals are in medical devices. They're particularly important for things like catheter seals where even small failures could be dangerous, or for covering surgical instruments during procedures. These practical applications show why silicone remains a top choice for maintaining proper hygiene levels in hospitals and clinics everywhere.

Optimizing Silicone Gasket Performance

Material Selection for Chemical Exposure

Getting the right silicone mix matters a lot when dealing with chemical exposure risks across different settings. Silicone comes in many forms, each with its own resistance level against various chemicals. Pick the wrong type and watch out for gasket problems down the road. Most industrial applications need silicones that stand up well against particular chemicals they'll encounter daily. Research from the Journal of Applied Polymer Science shows plenty of cases where companies picked materials that couldn't handle what was thrown at them, resulting in early gasket failures. That's why knowing exactly what works best for specific situations saves headaches later on. Taking time to evaluate options properly keeps operations running smoothly while making those silicone gaskets last much longer than expected.

Installation Techniques for Maximum Efficiency

Getting the installation of silicone gaskets right makes all the difference for how well they perform and how long they last. Many people make errors when putting them in place, things like not compressing evenly or getting the alignment wrong, which can really mess up the seal. This leads to leaks happening more often and the whole system just doesn't work as intended. Most industry standards stress out about preparation first things first. Clean those surfaces thoroughly before starting, and apply even pressure across the whole gasket while installing it. That helps get the best possible seal. There are plenty of good resources available too. Check out the installation guides put together by Silicone Engineering and similar companies. These materials walk through exactly what to do step by step so folks don't fall into common traps. Following these tips leads to better seals that actually hold up under real world conditions.

Predictive Maintenance Best Practices

Predictive maintenance really helps stretch out the lifespan of silicone gaskets while stopping those surprise breakdowns that nobody wants. These days, businesses can keep an eye on how their gaskets are doing thanks to things like IoT sensors and monitoring systems that track performance in real time. The Journal of Manufacturing Processes actually did some research showing that companies using predictive maintenance see their downtime drop by around 30% or more in many cases. When manufacturers put these methods into practice, they get better efficiency for sure, but what matters even more is that operations become much more reliable over time. This makes all the difference in industries where services just cannot afford any interruptions at all.

FAQ

What are the key benefits of silicone gaskets in industrial applications?

Silicone gaskets provide excellent resistance to extreme temperatures, chemical inertness, adaptive sealing on non-uniform surfaces, and durability in harsh environments, making them ideal for various industrial applications.

How can predictive maintenance be applied to silicone gaskets?

Predictive maintenance involves using IoT sensors and real-time monitoring tools to track gasket performance and identify potential issues before they escalate, thereby extending the gasket's life and preventing failures.

Why is material selection important when dealing with chemical exposure?

Material selection is crucial because different silicone formulations offer varying levels of chemical resistance, and choosing the wrong composition can lead to premature gasket failure and operational disruptions.