A Reliable Solution for Precision Fluid Transfer

In various industrial and medical settings, the need for reliable, consistent, and contamination-free fluid transfer is paramount. Among the most widely adopted materials in these applications is silicone tubing, especially when used in conjunction with peristaltic pumps. Silicone tubing offers an unmatched combination of flexibility, durability, and biocompatibility, making it an ideal choice for environments that demand sterility and precision. From pharmaceutical manufacturing to food processing and laboratory use, silicone tubing has carved out a central role due to its performance under pressure, ability to withstand repeated compression cycles, and compatibility with a wide range of chemicals. Whether dealing with viscous fluids, sensitive biological samples, or high-temperature solutions, industries rely on silicone tubing to maintain system integrity and product quality. As we delve deeper into the advantages of using silicone tubing with peristaltic pumps, it becomes clear why this combination continues to lead in both innovation and practicality.

Enhanced Flexibility and Compression Resistance

Ideal for Repetitive Pumping Action

Silicone tubing exhibits excellent flexibility, which is vital for the function of peristaltic pumps that rely on repetitive squeezing and releasing motions to move fluids. This elasticity allows the tubing to return to its original shape after each compression cycle without significant wear, maintaining consistent flow rates over extended periods of use. It resists kinking even in tight bending radii, making it suitable for compact systems where space is limited. The inherent resilience of silicone material helps ensure that flow pathways remain unobstructed, thus preserving pump performance and preventing pulsation irregularities that could otherwise compromise sensitive processes.

Longevity Under Continuous Use

Unlike many alternative materials, silicone tubing stands out for its remarkable ability to endure the mechanical fatigue associated with continuous use in peristaltic pumps. This is particularly important in industrial processes or laboratory automation where downtime can be costly and disruptive. With proper selection based on durometer and wall thickness, silicone tubing can operate efficiently for hundreds of hours without degradation, cracking, or collapsing. This durability reduces the frequency of maintenance interventions and tubing replacement, translating to lower operational costs and increased productivity. Over time, the use of high-grade silicone tubing offers better value, especially in applications demanding consistent, high-volume fluid transport.

Excellent Chemical and Thermal Resistance

Broad Chemical Compatibility

Silicone tubing’s molecular structure renders it resistant to a wide array of chemicals, making it well-suited for applications where exposure to solvents, acids, or alkalis is expected. This compatibility ensures that there is minimal risk of leaching or degradation when transferring sensitive fluids, preserving both the tubing and the medium it conveys. Whether used in biopharmaceutical processes, analytical instrumentation, or chemical dispensing systems, silicone tubing provides a reliable conduit for fluid transfer without altering the composition or purity of the contents. This reliability is a major factor behind its preference in regulated environments.

Performance Across Wide Temperature Ranges

Temperature extremes are a frequent challenge in fluid handling systems, especially in industrial or sterilization settings. Silicone tubing performs consistently across a broad temperature range, typically from -50°C to 200°C, making it highly adaptable to both cryogenic and high-temperature applications. It can withstand autoclaving and repeated sterilization cycles without compromising its physical integrity, which is essential for maintaining hygiene and compliance with regulatory standards. This thermal stability makes silicone tubing a dependable choice for fluid transfer systems exposed to varying or fluctuating thermal conditions, whether in steam sterilization or refrigeration environments.

Biocompatibility and Safety for Sensitive Applications

Preferred Material in Medical and Food Processing

Silicone tubing is widely recognized for its biocompatibility, which is crucial in medical, pharmaceutical, and food-related applications. It is non-reactive, non-toxic, and does not support bacterial growth, meeting the strict hygiene requirements demanded by these industries. Certified food-grade and medical-grade silicone formulations adhere to FDA, USP Class VI, and ISO 10993 standards, ensuring that they are safe for direct contact with consumable or injectable substances. This makes silicone tubing an excellent choice for transferring nutrient solutions, beverages, or intravenous medications, where purity and patient safety are non-negotiable.

Non-Leaching and Odor-Free Material

A critical feature of silicone tubing is its non-leaching nature, meaning it does not release any additives or byproducts into the fluids being transferred. This is particularly important in industries that require flavor or chemical neutrality, such as beverage manufacturing or analytical testing. Furthermore, silicone tubing is odorless and tasteless, ensuring that it does not interfere with the characteristics of consumable products. This neutral profile supports its use in applications where even minor contamination can lead to product rejection or regulatory non-compliance. As a result, silicone tubing remains the preferred solution where clean and uncontaminated fluid paths are essential.

Versatility Across Industrial Applications

Widely Used in Peristaltic Pump Systems

Peristaltic pumps are employed in a variety of sectors including laboratory research, wastewater treatment, chemical metering, and pharmaceutical processing. In each of these fields, silicone tubing is chosen for its ability to maintain precise and controllable flow rates without compromising system cleanliness. Its soft texture and smooth interior minimize flow disruption and help reduce the risk of clogging or buildup, especially when handling viscous or particulate-laden fluids. As industries evolve toward more automated and sterile fluid handling processes, the compatibility of silicone tubing with existing peristaltic pump designs continues to drive its widespread adoption.

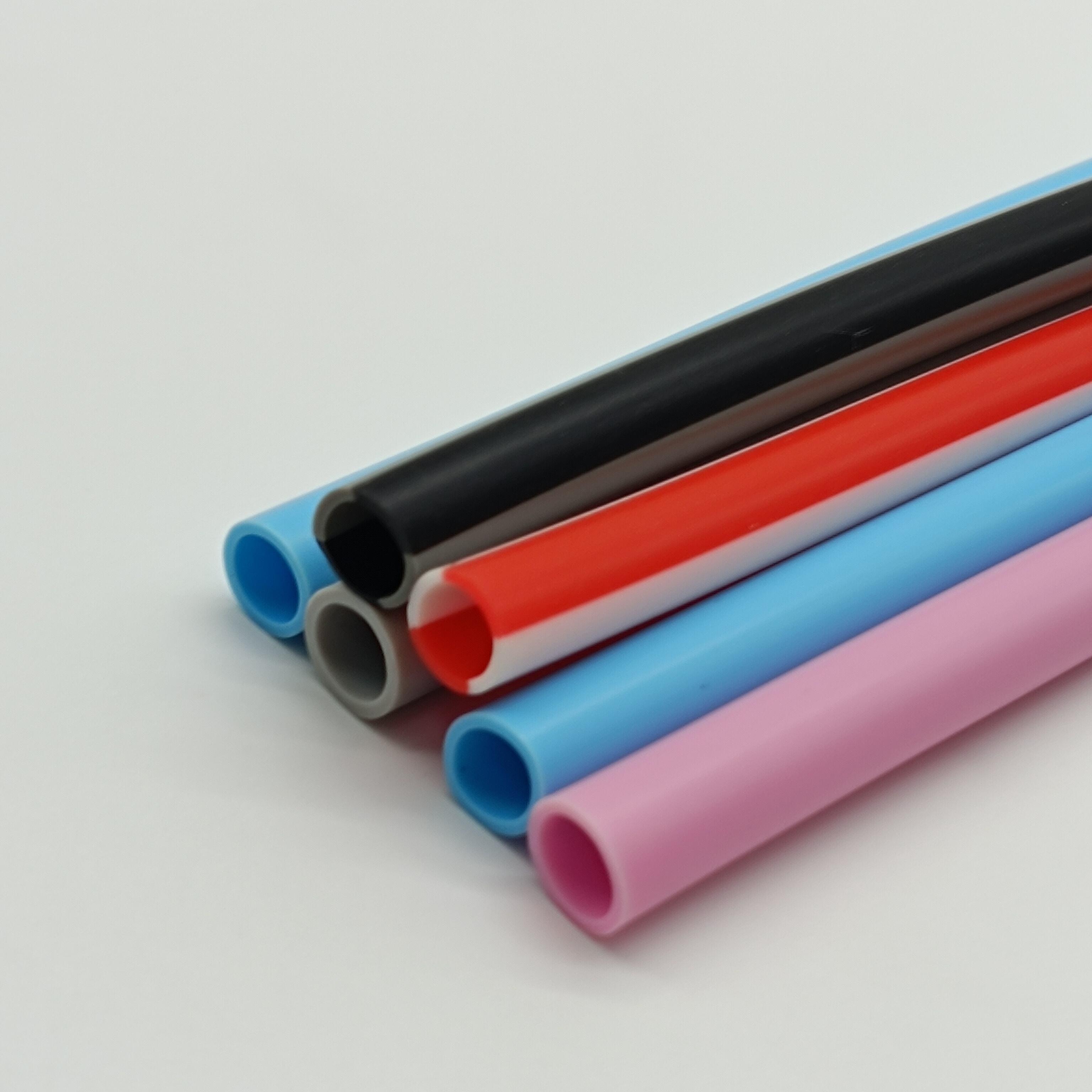

Customizable to Fit Specific System Needs

One of the major advantages of silicone tubing is its adaptability. It is available in various sizes, wall thicknesses, and durometer ratings, which allows engineers and technicians to select the most appropriate configuration for their specific needs. Whether for microfluidic setups requiring small-bore tubing or industrial-scale systems needing high-flow capabilities, silicone tubing can be tailored to meet performance specifications. This customization enhances operational efficiency and enables better integration into new or existing infrastructure, making it a highly flexible option for fluid transfer solutions.

Cost Efficiency and Operational Benefits

Reduced Downtime and Maintenance Costs

By offering long service life and resistance to mechanical and chemical stress, silicone tubing minimizes the frequency of replacement and system shutdowns. In high-throughput environments such as manufacturing plants or laboratories, these operational benefits translate to substantial cost savings over time. Moreover, because silicone tubing can endure multiple sterilization cycles without loss of integrity, it supports reuse and helps reduce consumables waste, aligning with sustainability goals. Lower maintenance requirements also mean fewer service calls and reduced labor input, streamlining workflows and keeping productivity on track.

Easy Installation and Replacement

Silicone tubing is easy to handle and install, which adds to its practicality. It can be cut, bent, and fitted without the need for specialized tools, allowing for quick integration into existing peristaltic pump systems. This user-friendly nature speeds up system assembly and reduces installation errors that can lead to leakage or inefficiency. For systems that require frequent configuration changes or quick line swaps, the ease of working with silicone tubing makes it especially valuable. This combination of performance and convenience enhances its overall utility in demanding operational settings.

FAQ

What makes silicone tubing suitable for peristaltic pumps?

Silicone tubing’s flexibility, chemical resistance, and biocompatibility make it ideal for peristaltic pumps. It handles repeated compression cycles without degrading and maintains a consistent flow rate.

Can silicone tubing be sterilized?

Yes, silicone tubing can withstand repeated sterilization methods such as autoclaving, making it perfect for medical and food applications where hygiene is crucial.

Is silicone tubing safe for food and beverage use?

Absolutely. Food-grade silicone tubing complies with FDA and other safety standards, making it safe for transferring beverages, dairy, and other consumables.

How long does silicone tubing last in a peristaltic pump?

The lifespan depends on use conditions, but high-quality silicone tubing can last hundreds of hours in peristaltic pumps before needing replacement.