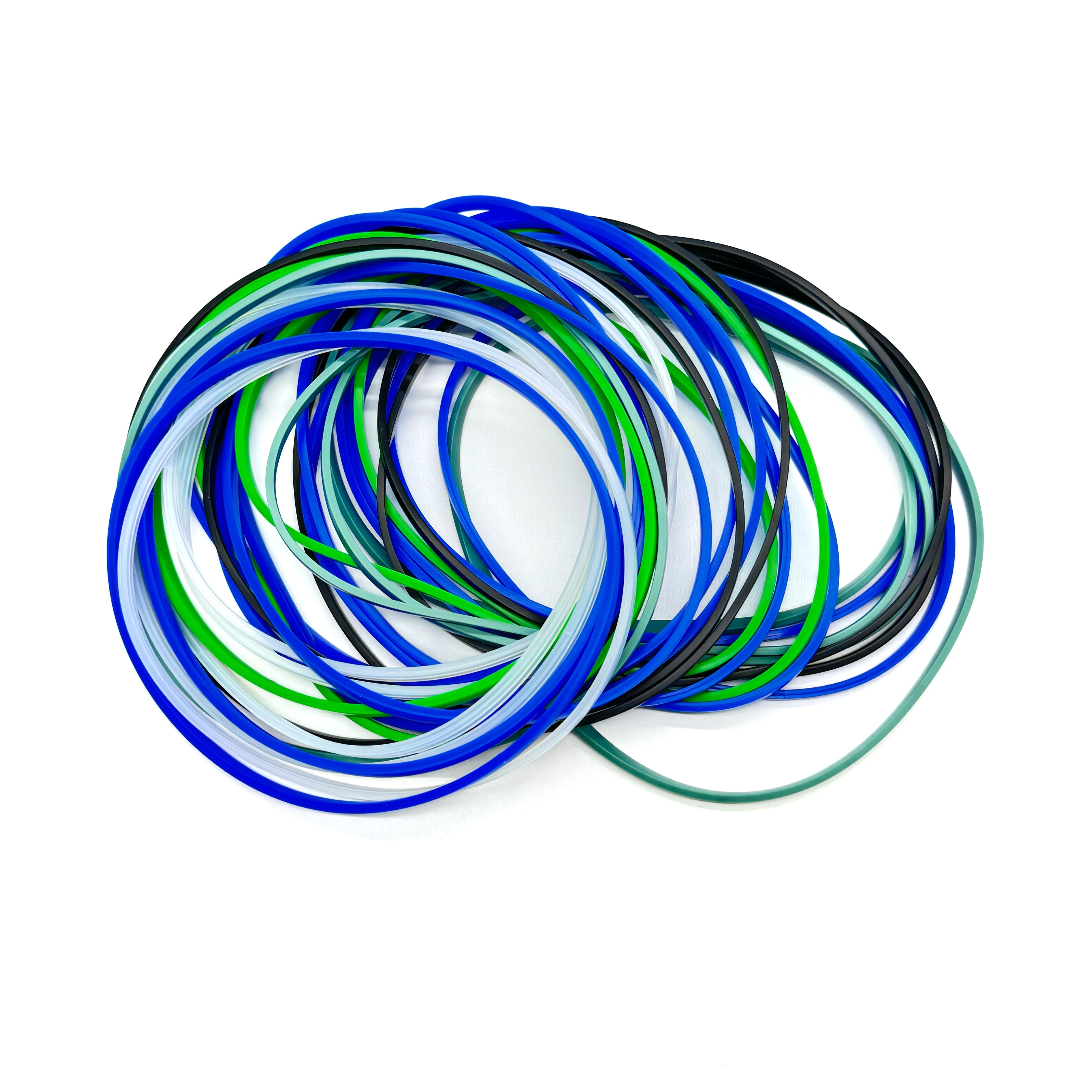

Superior Temperature Resistance of Silicone Gaskets

Withstanding Extreme Heat and Cold

Silicone gaskets can handle really extreme temperatures, anywhere between minus 65 degrees Fahrenheit down to as hot as 450 degrees F (which translates to about -54 Celsius up to around 232 Celsius). Because of this temperature range, they work great in places where there are big swings between super cold and super hot conditions. What makes silicone special is how it keeps its shape and stays flexible even when pressure changes happen suddenly. The material doesn't crack or lose its form no matter what kind of stress gets thrown at it. For folks working in fields like aerospace engineering or car manufacturing, this matters a lot since their machinery faces all sorts of tough environmental challenges daily. Take aircraft engines for instance they need seals that won't fail during flight despite rapid temperature shifts. That's why so many manufacturers depend on silicone's ability to resist temperature extremes for smooth day-to-day operations across various industrial settings.

Maintaining Flexibility Across Temperature Fluctuations

Silicone gaskets have a major advantage because they stay flexible and keep their elastic qualities even when temperatures swing wildly. What makes them so good at sealing? Well, unlike other materials that tend to get brittle or crack over time, silicone stays soft enough to form tight seals without leaking. We've seen this work in practice too. When put through those extreme temperature changes, silicone just keeps going without breaking down. Compared to older materials, silicone really stands out in how well it bends and stretches while still holding everything together securely. From freezing conditions to super hot environments, these gaskets perform reliably day after day, keeping their shape and doing the job they're meant to do without fail.

Unmatched Chemical and Environmental Durability

Resistance to Harsh Chemicals and Solvents

Silicone gaskets stand up pretty well against all sorts of corrosive chemicals, making them a must have in places like pharmaceutical labs and manufacturing plants. What makes these gaskets special is their ability to keep sealing properly even after running into aggressive substances. No breakdown means no leaks, which saves companies from expensive production stoppages and equipment damage. Take a look at what happens when exposed to common industrial threats like sulfuric acid, acetone, or hydraulic fluids the gaskets just keep working as intended. Because of this resilience, many facilities across different sectors choose silicone gaskets whenever there's going to be regular contact with harsh chemicals. Real world testing over decades confirms what engineers already know these materials simply perform better than alternatives in tough chemical environments.

Protection Against UV Radiation and Ozone Exposure

Silicone gaskets stand up pretty well against UV rays and ozone exposure, which makes them a solid choice for those tricky outdoor jobs where sunlight is constant. Unlike many other types of rubber that tend to break down after being out there too long, silicone just keeps going. Some field tests actually show these gaskets lasting around 10 full years in direct sunlight before showing much wear at all. The fact they last so long really matters for things like industrial equipment or building seals that get installed once and forgotten about. When those rubber parts fail prematurely, whole systems start acting up or even creating safety problems down the line.

In both sections, the unmatched chemical and environmental robustness of silicone gaskets proves invaluable across diverse sectors, delivering durability and stability in conditions that would challenge lesser materials.

Compliance with Safety and Regulatory Standards

FDA Approval for Food and Medical Applications

Silicone gaskets are made according to FDA requirements which makes them great choices for food processing lines and medical devices. They prevent harmful substances from getting into what we eat or medical tools patients rely on, keeping everyone safe from contamination risks. What really stands out about these gaskets is how they work across different settings while still meeting all necessary regulations. Food manufacturers love them for their durability around hot surfaces, while hospitals appreciate the fact that they won't react with chemicals used during procedures. The FDA seal basically confirms what many professionals already know - silicone remains inert even when exposed to extreme conditions, making it one of the most trusted materials in both kitchens and operating rooms where safety matters most.

Non-Toxic Properties and Biocompatibility

Silicone doesn't contain harmful substances, so it works well in situations where people might come into contact with it, like in medical devices or everyday items we use. The material actually gets along pretty well with our bodies too. That's why silicone gaskets show up so often in things like implants and hospital equipment. Major health organizations have tested these gaskets extensively and given them the green light for use in all sorts of delicate applications. These official approvals highlight just how important silicone gaskets are when it comes to keeping safety standards high in fields ranging from healthcare to food processing.

Long-Term Performance and Cost Efficiency

Low Compression Set for Reliable Sealing

Silicone gaskets stand out because they don't compress much over time, so they keep their shape and seal properly even after sitting there for ages. This means mechanics and plant workers don't have to replace them as often or fix leaks caused by worn out seals, which saves money in the long run. Real world tests show these gaskets last way longer than regular rubber ones. We're talking about parts staying functional in car engines and factory equipment for multiple years without losing effectiveness. With companies everywhere looking for better ways to seal things without constant maintenance, silicone has become a go to material. The simple fact is these gaskets just work better and last longer than almost any alternative on the market today.

Reduced Maintenance Needs and Lifespan Advantages

Silicone gaskets last much longer than other materials, which means they need maintenance far less often. This makes them a smart investment for companies looking at long term savings. Unlike rubber alternatives that crack or degrade over time, silicone gaskets rarely fail suddenly, so factories don't face unexpected shutdowns when parts give out. Many manufacturing plants have reported significant cost savings after switching to silicone, partly because these gaskets simply last years longer before replacement is needed. What's more, silicone stands up well against extreme temperatures and chemicals commonly found in industrial processes. For auto manufacturers dealing with engine heat or food processing facilities exposed to cleaning agents, this durability translates directly into fewer repairs and better compliance with safety regulations. As carmakers push for lighter vehicles and factory owners battle rising production costs, the economic advantages of silicone gaskets become increasingly hard to ignore.

Versatility Across Industrial Applications

Automotive and Aerospace Use Cases

Silicone gaskets matter a lot in cars, particularly inside engines and various systems because they handle heat really well. Most car engines run around 200°F but can spike much higher during operation, and these gaskets keep everything sealed properly despite that heat. When we look at airplanes and rockets, silicone gaskets are absolutely vital for keeping things safe and working right when parts get exposed to mind-blowing temperatures and pressure changes. They don't break down easily when hit with sunlight, chemical fumes, or ozone exposure either, which is why so many manufacturers specify them for aircraft construction. Mechanics and engineers who work on both ground vehicles and flying machines regularly point out how these gaskets hold up year after year even when pushed beyond normal operating limits.

Critical Roles in Healthcare and Electronics

Silicone gaskets play a crucial role in healthcare settings, especially in things like syringes and intravenous lines where keeping everything sterile is absolutely essential. What makes silicone stand out here is that it doesn't react with body fluids or tissues, so doctors can trust these seals won't mess with patient safety during procedures. When we look at electronics manufacturing too, silicone remains a go to material for creating protective barriers against water damage and dirt buildup. This protection really matters for gadgets with delicate circuitry inside them. The truth is most engineers working on medical equipment or consumer electronics have long since switched from rubber alternatives to silicone because they just work better over time. No one wants to deal with failed seals causing malfunctions or contamination risks down the road.

Silicone vs. Traditional Rubber Gaskets

Performance in Extreme Conditions

Silicone gaskets really shine when things get tough, beating regular rubber gaskets hands down when it comes to keeping seals tight. Regular old rubber tends to break down under intense temperatures, both hot and cold, but silicone stands its ground even when temps swing wildly from freezing to scorching. Lab tests keep showing the same thing time after time silicone stays put where rubber would crack or melt, which is why so many industrial operations rely on them for critical applications. Manufacturers across various sectors have been tracking these results for years now, and the numbers back it up completely. That's why we're seeing more and more companies switch to silicone gaskets whenever they need reliable sealing in harsh environments.

Cost-Benefit Analysis Over Time

Looking at the numbers shows silicone gaskets actually save money in the long run when compared to regular rubber ones. Sure they cost more at first, but these gaskets last way longer and need almost no maintenance, so the extra cash spent upfront pays off down the road. Many businesses working on important projects have seen real savings after making the switch to silicone materials. They spend less on replacements and can stretch out their maintenance schedules too. The initial price tag might seem steep, but what we find is that silicone gaskets just keep performing without fail year after year, delivering real economic advantages for anyone willing to invest in quality sealing solutions.

FAQ

What temperature range can silicone gaskets withstand?

Silicone gaskets can withstand temperatures ranging from -65°F to 450°F (-54°C to 232°C), making them suitable for environments with significant heat or cold fluctuations.

Are silicone gaskets resistant to harsh chemicals?

Yes, silicone gaskets exhibit impressive tolerance to various corrosive chemicals, such as acids, solvents, and oils, without compromising their performance.

Do silicone gaskets comply with FDA standards for food and medical applications?

Yes, silicone gaskets can be manufactured to meet strict FDA standards, making them ideal for food processing and medical equipment, ensuring user safety.

How do silicone gaskets compare to traditional rubber gaskets?

Silicone gaskets outperform traditional rubber gaskets, particularly in extreme conditions, due to their superior temperature resistance, chemical tolerance, and overall durability.

What are the maintenance advantages of using silicone gaskets?

Silicone gaskets require less frequent maintenance and have extended lifespans, contributing to lower operational costs for industries utilizing them.

Table of Contents

- Superior Temperature Resistance of Silicone Gaskets

- Unmatched Chemical and Environmental Durability

- Compliance with Safety and Regulatory Standards

- Long-Term Performance and Cost Efficiency

- Versatility Across Industrial Applications

- Silicone vs. Traditional Rubber Gaskets

-

FAQ

- What temperature range can silicone gaskets withstand?

- Are silicone gaskets resistant to harsh chemicals?

- Do silicone gaskets comply with FDA standards for food and medical applications?

- How do silicone gaskets compare to traditional rubber gaskets?

- What are the maintenance advantages of using silicone gaskets?