Professional bakers understand that the foundation of exceptional pastries lies not just in skill and ingredients, but also in the quality of tools used throughout the baking process. Among these essential tools, the silicone cake mold has revolutionized modern baking operations, offering unparalleled flexibility, durability, and ease of use that traditional metal pans simply cannot match. Whether you're operating a commercial bakery, running a small pastry shop, or managing a high-volume food service operation, selecting the right silicone cake mold can significantly impact your production efficiency, product quality, and overall profitability.

The transition from traditional baking methods to modern silicone technology represents more than just a material upgrade – it signifies a complete transformation in how professional kitchens approach consistency, presentation, and operational workflow. Understanding the nuances of silicone mold selection requires careful consideration of multiple factors including food grade certifications, temperature resistance, design complexity, and long-term durability under commercial use conditions.

Understanding Silicone Material Properties and Food Safety Standards

Food Grade Certification Requirements

When evaluating any silicone cake mold for commercial use, the first and most critical consideration must be food grade certification compliance. Legitimate food-grade silicone materials undergo rigorous testing to ensure they meet FDA, LFGB, and other international safety standards that govern direct food contact applications. These certifications guarantee that the silicone will not leach harmful chemicals, maintain structural integrity under repeated use, and resist degradation when exposed to various pH levels commonly found in baking ingredients.

Professional bakers should always verify that their chosen silicone cake mold carries proper documentation from recognized testing laboratories. This documentation typically includes migration testing results, which demonstrate that no harmful substances transfer from the mold material to food products during normal baking temperatures and contact times. Additionally, certified food-grade silicone exhibits superior resistance to staining, odor absorption, and bacterial growth, making it ideal for high-volume commercial applications where hygiene standards are paramount.

Temperature Resistance and Thermal Properties

The thermal characteristics of silicone materials directly impact their performance in professional baking environments. High-quality silicone cake molds typically withstand temperatures ranging from negative forty degrees Fahrenheit to over four hundred degrees Fahrenheit, making them suitable for everything from frozen dessert preparation to high-temperature baking applications. This temperature flexibility allows bakers to use the same mold for multiple processes, including freezing, baking, and even brief exposure to broiler conditions for specialized finishing techniques.

Understanding thermal conductivity properties helps bakers optimize their baking processes when using silicone molds. Unlike metal pans that conduct heat rapidly and create hot spots, silicone materials provide more even heat distribution, resulting in more consistent baking results across the entire product. This characteristic proves particularly valuable when producing delicate items like soufflés, custards, or temperature-sensitive chocolate creations where even heat distribution prevents unwanted texture variations or structural failures.

Design Complexity and Production Volume Considerations

Intricate Pattern Capabilities

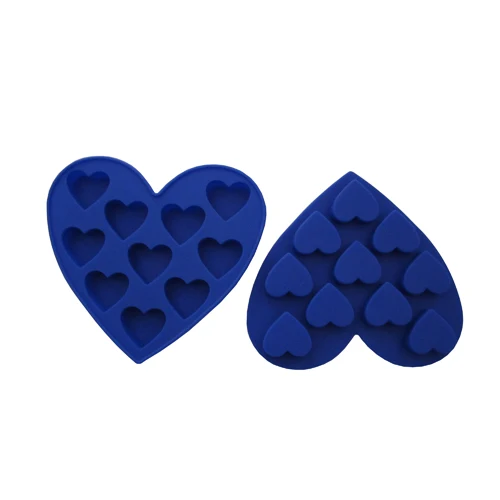

Modern silicone manufacturing techniques enable the creation of incredibly detailed and complex mold designs that would be impossible or prohibitively expensive to produce using traditional materials. The flexibility inherent in silicone allows for intricate undercuts, fine detail work, and complex geometric patterns that add significant visual appeal to finished products. Professional bakers can leverage these capabilities to create signature items that differentiate their offerings in competitive markets while maintaining consistent production efficiency.

The ability to reproduce fine details consistently across multiple production runs represents a significant advantage for bakeries focusing on premium or specialty products. Whether creating elaborate wedding cake components, detailed seasonal decorations, or branded corporate items, a well-designed silicone cake mold ensures that every piece meets exact specifications without requiring extensive hand-finishing or correction work that increases labor costs and production time.

Scalability for Commercial Operations

Successful commercial baking operations require equipment that can handle varying production volumes without compromising quality or efficiency. Silicone cake molds excel in this regard because they maintain their shape and performance characteristics even under intensive daily use. The material's resistance to warping, cracking, and degradation means that bakeries can rely on consistent results whether producing small artisanal batches or large-scale commercial runs.

The stackable nature of many silicone mold designs also contributes to operational efficiency by optimizing storage space and organizing workflow systems. Professional kitchens benefit from the ability to nest molds compactly when not in use, while their lightweight properties reduce handling fatigue during extended production periods. These practical considerations become increasingly important as production volumes scale up and labor efficiency directly impacts profitability margins.

Durability and Maintenance Requirements

Long-term Performance Under Commercial Use

The economic justification for investing in quality silicone cake molds becomes apparent when evaluating their lifespan compared to alternative materials. Professional-grade silicone maintains its flexibility, non-stick properties, and structural integrity through thousands of use cycles when properly maintained. This longevity translates to lower replacement costs and reduced downtime associated with equipment failure or performance degradation over time.

Commercial bakeries must consider the total cost of ownership when evaluating mold options, including initial purchase price, expected lifespan, maintenance requirements, and replacement frequency. High-quality silicone cake molds typically demonstrate superior return on investment because they eliminate the need for frequent replacement while maintaining consistent performance standards throughout their operational life. This reliability proves especially valuable in production environments where equipment failure can result in significant lost revenue and customer dissatisfaction.

Cleaning and Sanitation Protocols

Effective cleaning and sanitization procedures are essential for maintaining food safety standards in commercial baking operations. Silicone materials offer significant advantages in this regard because their non-porous surface resists bacterial growth and allows for thorough cleaning without aggressive scrubbing that might damage the mold surface. Most silicone cake molds can be safely cleaned using standard commercial dishwashing systems, although hand washing with appropriate detergents often provides superior results for maintaining mold condition.

The chemical resistance of quality silicone enables the use of professional sanitizing agents without concern for material degradation or contamination. This compatibility with commercial cleaning protocols ensures that molds can be properly sanitized between uses while maintaining their performance characteristics. Additionally, the transparency of many silicone materials allows visual inspection for cleanliness verification, providing an extra layer of quality assurance that opaque materials cannot offer.

Size Variations and Portion Control Benefits

Standardizing Portion Sizes for Cost Control

Consistent portion control represents one of the most critical factors in maintaining profitability within commercial baking operations. Silicone cake molds provide precise volume control that ensures every product meets exact specifications, eliminating waste associated with oversized portions or customer dissatisfaction from undersized servings. This precision becomes increasingly important when dealing with expensive ingredients or when pricing structures depend on exact portion sizes.

The dimensional stability of silicone materials means that portion sizes remain consistent even after extended use, unlike some materials that may warp or change shape over time. This reliability allows bakeries to establish accurate costing models and maintain consistent profit margins across their product lines. Professional operations can confidently calculate ingredient costs, labor requirements, and pricing structures knowing that their silicone cake molds will deliver predictable results batch after batch.

Accommodating Diverse Product Lines

Modern bakeries often need to accommodate diverse product offerings ranging from individual portions to large celebration cakes. The availability of silicone molds in numerous sizes and configurations allows operations to maintain consistency across their entire product range while using standardized processes and equipment. This versatility reduces training requirements, simplifies inventory management, and enables efficient workflow organization throughout the production facility.

The ability to use similar handling, baking, and finishing techniques across different product sizes streamlines operations and reduces the likelihood of errors or inconsistencies. Staff members can apply their expertise across multiple product lines without needing specialized knowledge for each different mold type or material. This operational efficiency translates to reduced training costs, improved quality consistency, and enhanced overall productivity in commercial baking environments.

Non-stick Properties and Release Characteristics

Optimizing Product Release and Presentation

The superior release properties of quality silicone cake molds eliminate many common problems associated with traditional baking pans, including sticking, tearing, and surface damage during demolding. This reliability ensures that finished products maintain their intended appearance and structural integrity, reducing waste associated with damaged items and improving overall presentation quality. Professional bakers can achieve consistent results without relying heavily on release agents that may affect product taste or appearance.

The natural non-stick characteristics of silicone materials improve over time with proper use and maintenance, making older molds often perform better than new ones. This phenomenon occurs because the silicone surface develops a seasoned coating that enhances release properties while maintaining food safety standards. Understanding this characteristic helps bakeries optimize their mold rotation and replacement schedules to maximize performance while controlling equipment costs.

Reducing Production Time and Labor Costs

Efficient demolding processes directly impact production efficiency and labor costs in commercial baking operations. The excellent release properties of silicone cake molds significantly reduce the time required for product removal, allowing staff members to process more batches within standard shift periods. This efficiency gain becomes particularly valuable during peak production periods or when dealing with time-sensitive orders that require rapid turnaround.

The reduced need for extensive greasing or flouring also streamlines preparation processes while eliminating material waste associated with release agents. Professional kitchens benefit from simplified workflow procedures that reduce the opportunity for errors while maintaining consistent quality standards. These operational improvements contribute to enhanced profitability through reduced labor costs and improved production capacity utilization.

FAQ

How long do professional-grade silicone cake molds typically last in commercial use

Professional-grade silicone cake molds can last anywhere from two to five years in intensive commercial use, depending on usage frequency, maintenance practices, and quality of the original material. High-volume operations that use molds multiple times daily should expect replacement every two to three years, while moderate-use facilities may achieve four to five years of service life. Proper cleaning, avoiding sharp utensils, and following manufacturer temperature guidelines significantly extend mold lifespan and maintain consistent performance throughout their operational life.

Can silicone cake molds be safely used in convection ovens and steam injection systems

Yes, quality food-grade silicone cake molds are compatible with convection ovens, steam injection systems, and most commercial baking equipment. The material's excellent temperature stability and moisture resistance make it suitable for various baking environments, including high-humidity conditions created by steam injection. However, bakers should verify that their specific molds carry appropriate temperature ratings for their equipment and applications, as some specialized high-temperature processes may exceed standard silicone limitations.

What factors should be considered when selecting mold sizes for a new bakery operation

New bakery operations should consider their target market demographics, average order sizes, storage capacity, and production volume projections when selecting silicone cake mold sizes. Individual portion molds work well for retail operations and cafes, while larger molds suit custom cake businesses and wholesale operations. It's generally advisable to start with versatile mid-size options that can accommodate various applications, then expand the collection based on actual customer demand patterns and operational experience. Consider also the relationship between mold size and oven capacity to optimize batch efficiency.

Are there specific maintenance procedures that extend silicone mold lifespan in commercial settings

Extending silicone mold lifespan requires following proper cleaning procedures, avoiding sharp utensils that can create cuts or tears, and storing molds in ways that prevent deformation. Use mild detergents and avoid abrasive cleaning tools that can damage the surface texture. Allow molds to cool completely before cleaning, and ensure they are thoroughly dry before storage to prevent mold or mildew growth. Periodic deep cleaning with specialized silicone cleaners removes accumulated oils and maintains optimal release properties throughout the mold's service life.

Table of Contents

- Understanding Silicone Material Properties and Food Safety Standards

- Design Complexity and Production Volume Considerations

- Durability and Maintenance Requirements

- Size Variations and Portion Control Benefits

- Non-stick Properties and Release Characteristics

-

FAQ

- How long do professional-grade silicone cake molds typically last in commercial use

- Can silicone cake molds be safely used in convection ovens and steam injection systems

- What factors should be considered when selecting mold sizes for a new bakery operation

- Are there specific maintenance procedures that extend silicone mold lifespan in commercial settings