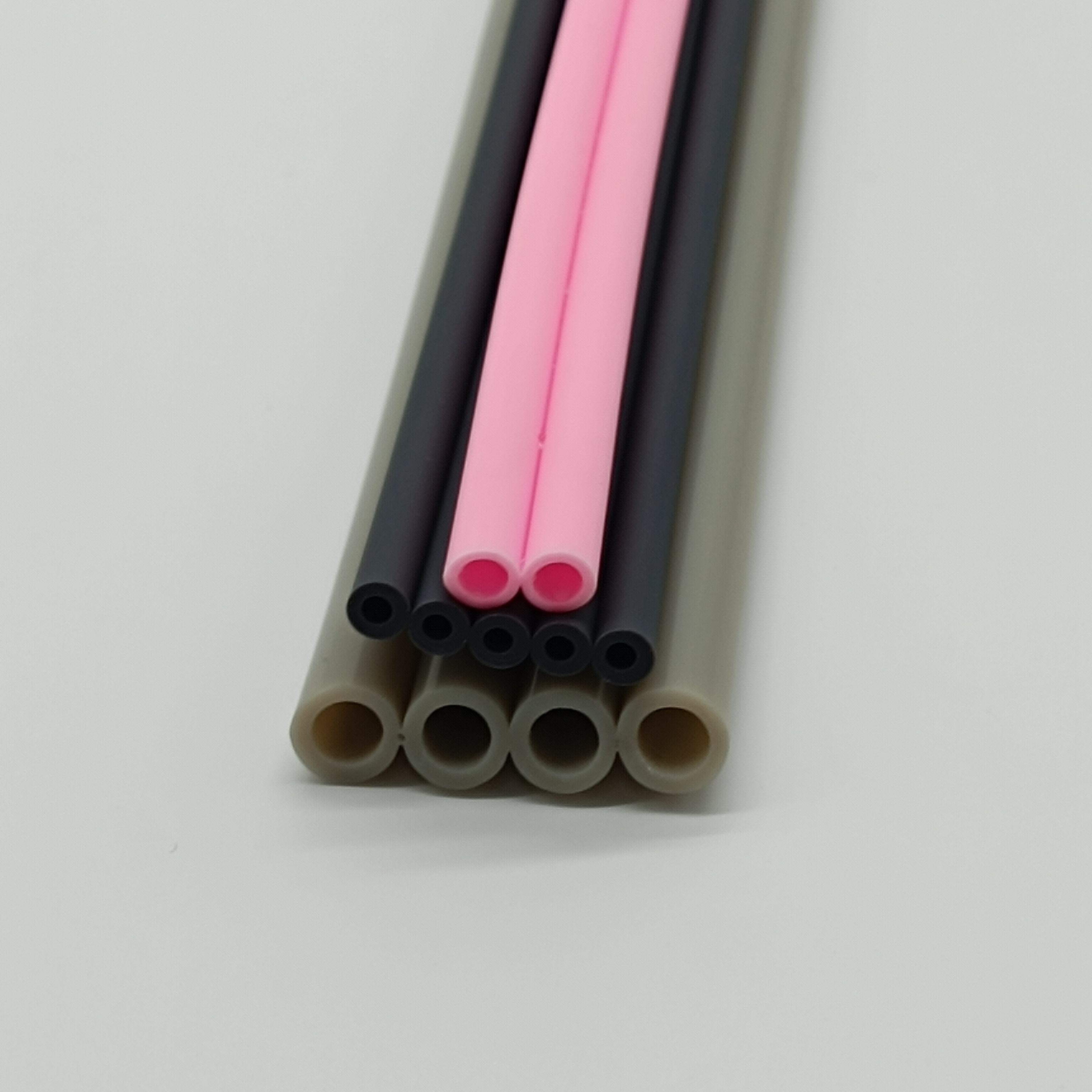

Laboratory environments demand the highest standards of safety, precision, and reliability when it comes to fluid transfer and containment systems. The choice of tubing material can significantly impact experimental outcomes, equipment longevity, and overall operational efficiency. Among the various options available, flexible silicone tube has emerged as a preferred solution for countless laboratory applications due to its exceptional properties and versatile performance characteristics. This advanced material offers a unique combination of chemical resistance, temperature stability, and mechanical flexibility that makes it indispensable in modern scientific research facilities.

Chemical Resistance and Inert Properties

Superior Chemical Compatibility

One of the most compelling advantages of flexible silicone tube in laboratory settings is its remarkable chemical inertness and broad compatibility with various substances. Unlike traditional rubber or plastic tubing materials, silicone exhibits exceptional resistance to acids, bases, alcohols, and many organic solvents commonly used in research applications. This chemical stability ensures that the tubing material does not react with or contaminate samples, maintaining the integrity of experimental results and preventing costly equipment damage or sample loss.

The molecular structure of silicone creates a barrier that resists chemical degradation even when exposed to aggressive compounds for extended periods. This property is particularly valuable in analytical chemistry, pharmaceutical research, and biotechnology applications where sample purity is paramount. Researchers can confidently use silicone tubing for transferring reactive chemicals, corrosive solutions, and sensitive biological fluids without worrying about material breakdown or leaching of unwanted substances into their samples.

Non-Reactive Surface Properties

The non-reactive nature of silicone surfaces minimizes protein binding and cellular adhesion, making it an ideal choice for biological and medical research applications. This characteristic prevents sample loss due to adsorption onto the tubing walls and ensures accurate measurements and consistent results. The smooth, non-porous surface of flexible silicone tube also facilitates easy cleaning and sterilization protocols, reducing the risk of cross-contamination between experiments.

Furthermore, the inherent properties of silicone prevent the growth of bacteria and other microorganisms on the tubing surface, contributing to a sterile working environment. This antimicrobial resistance is especially crucial in cell culture work, microbiological studies, and pharmaceutical manufacturing processes where contamination control is essential for regulatory compliance and experimental success.

Temperature Stability and Thermal Performance

Wide Operating Temperature Range

Laboratory processes often involve extreme temperature conditions that can challenge conventional tubing materials. Flexible silicone tube excels in this regard, maintaining its mechanical properties and chemical resistance across an impressive temperature range typically spanning from -65°C to +200°C or higher. This thermal stability allows researchers to use the same tubing system for both cryogenic applications and high-temperature processes without material degradation or performance compromise.

The ability to withstand thermal cycling without becoming brittle or losing flexibility is particularly valuable in automated laboratory systems where temperature variations are common. Whether transferring liquid nitrogen for sample preservation or handling heated reagents in chemical synthesis, flexible silicone tube maintains consistent performance throughout the temperature spectrum, ensuring reliable operation and reducing the need for multiple tubing types in a single laboratory setup.

Autoclave and Sterilization Compatibility

Sterilization is a critical requirement in many laboratory applications, particularly in microbiology, cell culture, and pharmaceutical research. Flexible silicone tube can withstand repeated autoclave cycles at standard sterilization temperatures without losing its mechanical properties or developing cracks and deformations. This durability significantly reduces replacement costs and ensures that sterile conditions can be maintained throughout extended research projects.

The material's resistance to steam sterilization, gamma radiation, and chemical disinfectants provides multiple sterilization options to suit different laboratory protocols and regulatory requirements. This versatility is especially important in research facilities that must comply with strict contamination control standards or work with pathogenic materials requiring validated sterilization procedures.

Mechanical Properties and Flexibility Advantages

Exceptional Flexibility and Bend Resistance

The mechanical characteristics of flexible silicone tube make it an outstanding choice for laboratory applications requiring frequent movement, tight radius bends, or complex routing configurations. Unlike rigid plastic tubing that may crack under stress or flexible rubber that can develop kinks and flow restrictions, silicone maintains its structural integrity while providing excellent flexibility and elasticity.

This flexibility advantage is particularly evident in applications involving robotic systems, automated samplers, and portable analytical equipment where the tubing must accommodate movement without compromising flow rates or creating pressure drops. The material's ability to return to its original shape after deformation prevents permanent kinking and ensures consistent fluid transfer characteristics throughout the equipment's operational life.

Durability and Longevity

Laboratory equipment represents a significant investment, and the longevity of consumable components like tubing directly impacts operational costs and research continuity. Flexible silicone tube demonstrates exceptional durability under normal laboratory conditions, often lasting significantly longer than alternative materials such as PVC, polyurethane, or natural rubber tubing.

The material's resistance to ozone, UV radiation, and environmental aging means that even tubing exposed to ambient laboratory conditions maintains its properties over extended periods. This longevity reduces the frequency of tubing replacement, minimizes system downtime for maintenance, and ensures consistent performance throughout long-term research projects where equipment reliability is crucial for data integrity.

Safety and Regulatory Compliance

Biocompatibility and Food Grade Standards

Safety considerations are paramount in laboratory environments, particularly when working with materials that may come into contact with biological samples, food products, or pharmaceutical compounds. High-quality flexible silicone tube meets stringent biocompatibility standards including USP Class VI, FDA CFR 177.2600, and European Pharmacopoeia requirements, ensuring safe use in critical applications.

The material's compliance with food grade standards makes it suitable for research involving food science, nutrition studies, and beverage analysis where sample integrity and safety are essential. This regulatory approval eliminates concerns about toxic leachates or harmful additives that might compromise experimental results or pose health risks to laboratory personnel.

Low Extractable Content

Analytical accuracy depends heavily on minimizing interference from external sources, including the materials used in sample handling systems. Flexible silicone tube exhibits extremely low levels of extractable compounds, reducing the risk of analytical interference and ensuring that trace analysis results accurately reflect sample composition rather than contamination from the tubing material.

This characteristic is especially important in pharmaceutical development, environmental analysis, and quality control applications where even minute levels of contamination can invalidate results or lead to regulatory compliance issues. The low extractable profile of silicone tubing contributes to method validation and supports reliable analytical data generation across diverse research disciplines.

Installation and Maintenance Benefits

Easy Installation and Connection

The physical properties of flexible silicone tube facilitate straightforward installation and connection to laboratory equipment. The material's flexibility allows for easy routing through tight spaces and around obstacles, while its elastic nature enables secure connections to fittings and connectors without requiring excessive force or specialized tools.

The smooth exterior surface reduces friction during installation, making it easier to thread tubing through protective conduits or equipment housings. Additionally, the material's resistance to stress cracking ensures that connections remain secure even when subjected to vibration or thermal cycling, reducing the likelihood of unexpected failures during critical experiments.

Simplified Cleaning and Maintenance

Maintenance efficiency directly impacts laboratory productivity and operational costs. Flexible silicone tube simplifies cleaning procedures due to its smooth, non-porous surface that resists buildup of residues and contaminants. The material can be cleaned using standard laboratory detergents, acids, bases, or organic solvents without degradation, allowing for thorough decontamination between uses.

The chemical compatibility of silicone with various cleaning agents means that researchers can use aggressive cleaning protocols when necessary without compromising tubing integrity. This capability is particularly valuable in applications involving sticky or difficult-to-remove substances that might require multiple cleaning cycles or harsh solvents for complete removal.

FAQ

How does flexible silicone tube compare to other tubing materials in terms of cost-effectiveness?

While the initial purchase price of flexible silicone tube may be higher than some alternatives like PVC or rubber tubing, its exceptional durability, chemical resistance, and temperature stability typically result in lower total cost of ownership. The extended service life, reduced replacement frequency, and elimination of contamination-related sample losses often justify the initial investment, particularly in critical applications where reliability is essential.

Can flexible silicone tube be used with high-pressure applications in laboratory settings?

Yes, flexible silicone tube can handle moderate to high-pressure applications depending on the wall thickness and reinforcement configuration. Standard silicone tubing typically operates safely at pressures up to 50-100 PSI, while reinforced versions can handle significantly higher pressures. Always consult manufacturer specifications and conduct pressure testing to ensure safe operation within your specific application requirements.

What precautions should be taken when using flexible silicone tube with organic solvents?

While silicone demonstrates excellent resistance to many organic solvents, compatibility should be verified for specific chemicals and concentrations used in your applications. Some highly aggressive solvents or specific chemical combinations may cause swelling or degradation over time. Conduct compatibility testing with your specific chemicals and monitor tubing condition regularly when using aggressive solvents to ensure continued safe operation.

How should flexible silicone tube be stored to maintain its properties over time?

Proper storage of flexible silicone tube involves keeping it in a clean, dry environment away from direct sunlight and extreme temperatures. The material should be stored in its natural state without excessive bending or compression to prevent stress concentration. Unlike some rubber materials, silicone does not require special atmospheric conditions or protective treatments, making long-term storage straightforward and cost-effective.

Table of Contents

- Chemical Resistance and Inert Properties

- Temperature Stability and Thermal Performance

- Mechanical Properties and Flexibility Advantages

- Safety and Regulatory Compliance

- Installation and Maintenance Benefits

-

FAQ

- How does flexible silicone tube compare to other tubing materials in terms of cost-effectiveness?

- Can flexible silicone tube be used with high-pressure applications in laboratory settings?

- What precautions should be taken when using flexible silicone tube with organic solvents?

- How should flexible silicone tube be stored to maintain its properties over time?