Industrial sealing systems face constant challenges from environmental factors, operational stress, and material degradation over time. The choice of gasket material significantly impacts the frequency and cost of maintenance operations across manufacturing facilities, automotive applications, and infrastructure systems. Understanding how advanced sealing materials contribute to reduced maintenance requirements helps engineers and facility managers make informed decisions that optimize both performance and operational costs.

Material Properties That Minimize Maintenance Requirements

Chemical Resistance and Longevity

Silicone gaskets demonstrate exceptional resistance to a wide range of chemicals, oils, and solvents commonly encountered in industrial environments. This chemical stability prevents premature degradation that typically requires frequent gasket replacements in traditional rubber sealing systems. The molecular structure of silicone creates strong silicon-oxygen bonds that maintain integrity even when exposed to aggressive chemical environments over extended periods.

The superior chemical resistance translates directly into reduced maintenance schedules, as facilities can operate longer intervals between gasket inspections and replacements. Manufacturing plants processing corrosive materials benefit significantly from this extended service life, reducing both material costs and labor expenses associated with routine maintenance activities.

Temperature Stability Across Operating Ranges

Temperature fluctuations represent one of the primary causes of gasket failure in conventional sealing systems. Silicone gaskets maintain their sealing properties across temperature ranges from -65°F to 400°F, far exceeding the capabilities of standard rubber materials. This thermal stability prevents the hardening, cracking, and dimensional changes that necessitate frequent replacements in systems experiencing temperature variations.

Industrial heating and cooling systems particularly benefit from this temperature resistance, as gasket failures in these applications often result in costly downtime and emergency repairs. The ability to withstand thermal cycling without losing elasticity or compression set resistance ensures consistent sealing performance throughout the operational lifecycle.

Performance Characteristics Reducing System Downtime

Compression Set Resistance

Compression set resistance measures a gasket's ability to return to its original thickness after being compressed for extended periods. Silicone gaskets exhibit superior compression set resistance compared to conventional rubber materials, maintaining effective sealing force over longer periods without requiring bolt retorquing or gasket adjustments.

This characteristic directly impacts maintenance requirements by eliminating the need for periodic bolt tightening procedures that are common with materials that lose their elastic recovery properties. Systems equipped with silicone sealing solutions require fewer scheduled maintenance interventions, allowing operational teams to focus resources on critical equipment rather than routine gasket maintenance.

Weather and UV Resistance

Outdoor installations and systems exposed to weathering conditions benefit significantly from the inherent weather resistance of silicone materials. Unlike organic rubber compounds that degrade under UV exposure and ozone attack, silicone gaskets maintain their physical properties and sealing effectiveness even after prolonged environmental exposure.

The elimination of weather-related degradation reduces the frequency of gasket inspections and replacements in outdoor equipment, HVAC systems, and building envelope applications. Facilities can extend maintenance intervals and reduce the labor costs associated with accessing and servicing exterior sealing points.

Economic Impact of Reduced Maintenance Cycles

Labor Cost Optimization

Maintenance labor represents a significant operational expense in industrial facilities, particularly when sealing system failures require emergency repairs or unscheduled downtime. The extended service life of silicone gaskets reduces the frequency of maintenance interventions, allowing maintenance teams to allocate resources more efficiently across facility operations.

Scheduled maintenance windows can be extended when using silicone sealing solutions, reducing overtime costs and minimizing the impact on production schedules. The predictable performance characteristics of these materials enable maintenance managers to develop more accurate maintenance forecasting and resource allocation strategies.

Inventory Management Benefits

Reduced gasket replacement frequency directly impacts spare parts inventory requirements and associated carrying costs. Facilities using silicone gaskets can maintain smaller gasket inventories while still ensuring adequate spare parts availability for planned maintenance activities. This inventory optimization frees up working capital and reduces warehouse space requirements.

The standardization possible with silicone materials also simplifies inventory management, as single gasket specifications can often serve multiple applications that previously required different material types. This consolidation reduces procurement complexity and enables bulk purchasing advantages.

Application-Specific Maintenance Advantages

Automotive and Transportation Systems

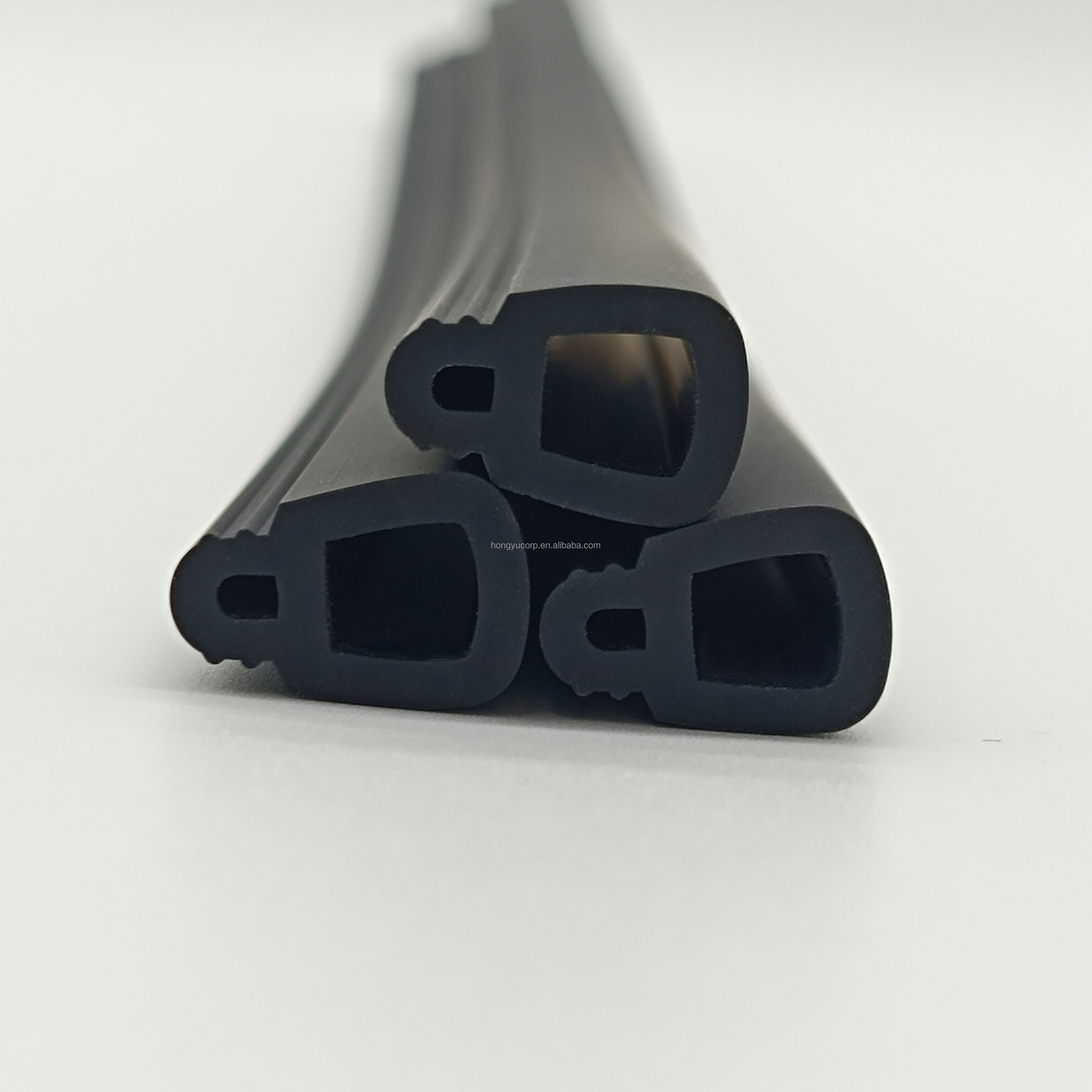

Automotive applications demand sealing solutions that maintain performance under dynamic operating conditions, including vibration, temperature cycling, and exposure to automotive fluids. Silicone gaskets in door seals, window systems, and engine compartment applications demonstrate significantly longer service intervals compared to traditional rubber seals.

Fleet maintenance operations benefit from reduced gasket replacement schedules, lowering vehicle downtime and maintenance costs. The consistent sealing performance also contributes to improved passenger comfort and vehicle weatherproofing throughout the service life.

Food Processing and Pharmaceutical Industries

Industries requiring frequent cleaning and sterilization procedures benefit from silicone gaskets' resistance to cleaning chemicals and high-temperature sterilization cycles. The material's non-porous surface prevents bacterial growth and facilitates thorough cleaning without compromising gasket integrity.

Reduced gasket replacement frequency in food processing equipment minimizes production interruptions and maintains hygienic standards more effectively than conventional rubber seals that may require frequent replacement due to cleaning-related degradation.

Installation and Design Considerations

Proper Installation Techniques

Maximizing the maintenance reduction benefits of silicone gaskets requires proper installation techniques that account for the material's unique characteristics. Unlike harder rubber materials, silicone gaskets may require specific torque specifications and installation procedures to optimize sealing performance and longevity.

Training maintenance personnel on proper installation techniques ensures that the full maintenance reduction benefits are realized in practice. Proper installation prevents premature failure and maximizes the return on investment in higher-quality sealing materials.

System Design Optimization

Sealing system design can be optimized to take advantage of silicone gaskets' superior properties, potentially simplifying gasket geometries and reducing the number of sealing points required. This design optimization further reduces maintenance requirements by minimizing the total number of potential failure points in the system.

Engineers can design longer maintenance intervals into systems when specifying silicone sealing solutions, allowing for more efficient scheduling of planned maintenance activities and reducing the total cost of ownership for sealing systems.

FAQ

How long do silicone gaskets typically last compared to rubber gaskets?

Silicone gaskets generally provide 2-5 times longer service life than conventional rubber gaskets, depending on the application and environmental conditions. In moderate temperature applications, silicone gaskets can maintain effective sealing for 10-20 years, while rubber gaskets may require replacement every 3-7 years. The exact service life depends on factors such as temperature exposure, chemical contact, and mechanical stress.

Do silicone gaskets require different installation procedures than rubber gaskets?

Silicone gaskets may require slightly different installation torque specifications due to their unique compression characteristics. Generally, silicone materials are softer than conventional rubber, requiring careful attention to avoid over-compression that could cause extrusion or under-compression that might compromise sealing effectiveness. Following manufacturer installation guidelines ensures optimal performance and longevity.

Are silicone gaskets cost-effective despite higher initial material costs?

While silicone gaskets typically have higher upfront costs than rubber alternatives, the total cost of ownership is often lower due to reduced maintenance frequency, longer service life, and decreased downtime. The extended replacement intervals and reduced labor costs for maintenance activities typically offset the higher initial material investment within the first service cycle.

Can silicone gaskets be used in all applications where rubber gaskets are currently used?

Silicone gaskets are suitable for most applications currently using rubber gaskets, but certain specific conditions may require evaluation. Applications involving petroleum-based fuels or certain aggressive solvents may require specialized silicone formulations or alternative materials. Consulting with gasket manufacturers ensures proper material selection for specific operating conditions and performance requirements.

Table of Contents

- Material Properties That Minimize Maintenance Requirements

- Performance Characteristics Reducing System Downtime

- Economic Impact of Reduced Maintenance Cycles

- Application-Specific Maintenance Advantages

- Installation and Design Considerations

-

FAQ

- How long do silicone gaskets typically last compared to rubber gaskets?

- Do silicone gaskets require different installation procedures than rubber gaskets?

- Are silicone gaskets cost-effective despite higher initial material costs?

- Can silicone gaskets be used in all applications where rubber gaskets are currently used?