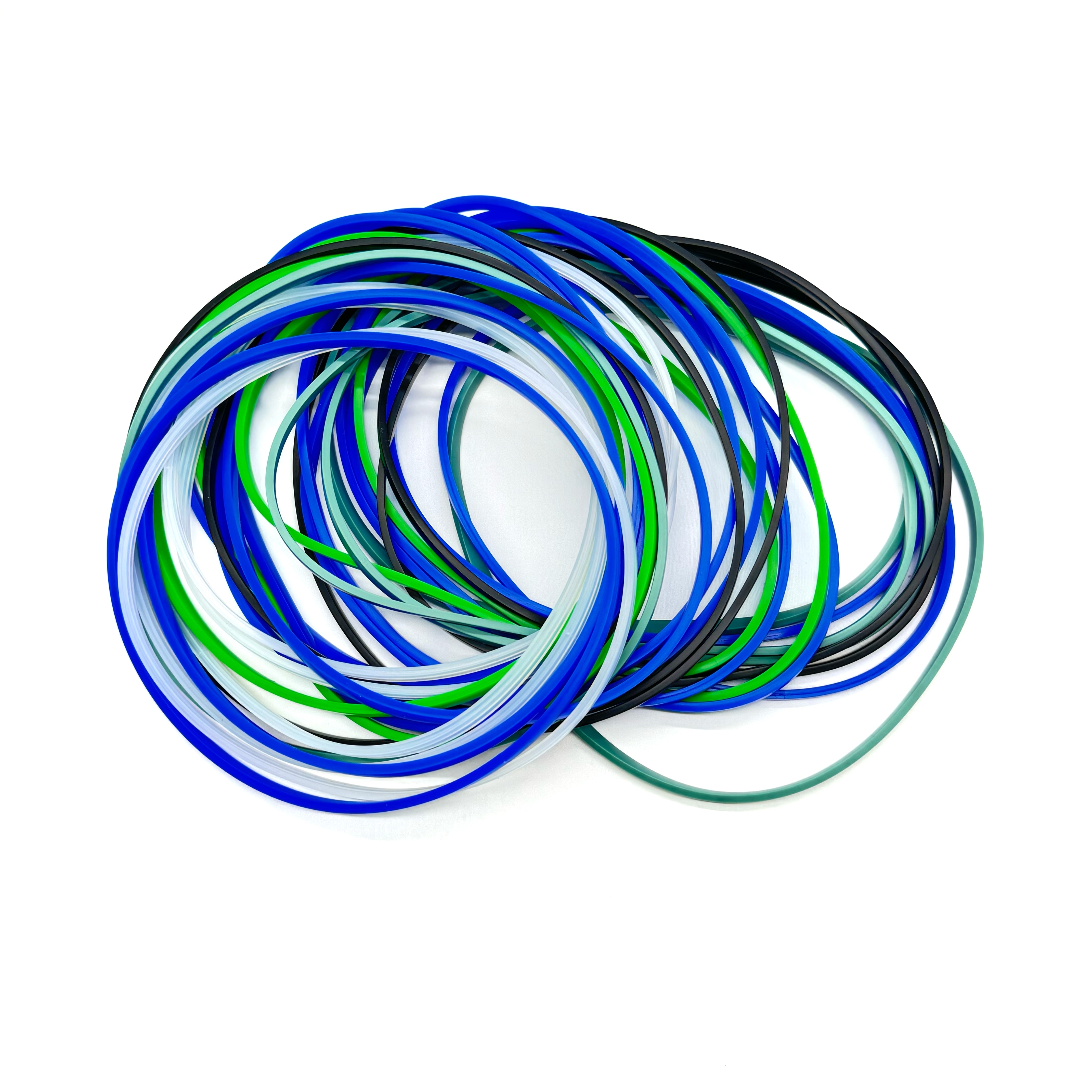

Industrial applications across automotive, aerospace, and manufacturing sectors increasingly rely on high-performance sealing solutions that can withstand extreme conditions while maintaining consistent performance over extended periods. Silicone gaskets have emerged as the preferred choice for engineers seeking reliable sealing components that deliver exceptional durability, chemical resistance, and temperature stability. Understanding the critical design features that enhance the longevity of these essential components enables manufacturers to make informed decisions when specifying sealing solutions for demanding applications.

The durability of silicone gaskets depends heavily on sophisticated design considerations that address material properties, geometric configurations, and environmental resistance factors. Modern gasket design integrates advanced polymer chemistry with precision engineering to create sealing solutions that maintain their integrity under challenging operating conditions. These design innovations have revolutionized sealing technology, enabling applications in environments previously considered unsuitable for elastomeric sealing components.

Material Composition and Polymer Structure

Advanced Silicone Formulations

The foundation of durable silicone gaskets lies in the careful selection and optimization of silicone polymer formulations that provide superior mechanical properties and environmental resistance. High-quality silicone gaskets utilize platinum-cured silicone compounds that offer enhanced cross-linking density, resulting in improved tensile strength, elongation characteristics, and compression set resistance. These advanced formulations incorporate specialized additives such as silica reinforcing fillers, which significantly enhance the mechanical properties of the base polymer while maintaining the inherent flexibility and temperature resistance that make silicone an ideal gasket material.

Manufacturers optimize the molecular weight distribution of silicone polymers to achieve the optimal balance between processability and final performance characteristics. The incorporation of functional additives such as heat stabilizers, UV inhibitors, and antioxidants extends the service life of gaskets by protecting the polymer matrix from degradation mechanisms that commonly occur in harsh operating environments. These formulation advances enable silicone gaskets to maintain their sealing effectiveness throughout extended service intervals, reducing maintenance requirements and improving system reliability.

Cross-Linking Technology and Cure Systems

The durability of silicone gaskets is fundamentally influenced by the cross-linking technology employed during the vulcanization process, with platinum-catalyzed addition cure systems providing superior performance compared to traditional peroxide cure systems. Platinum cure technology creates stable carbon-silicon bonds that resist thermal degradation and maintain mechanical properties over extended temperature cycling. This advanced curing chemistry eliminates the formation of volatile byproducts that can compromise gasket performance in sensitive applications such as food processing or pharmaceutical manufacturing.

Modern cross-linking systems enable precise control over the final hardness, compression modulus, and elastic recovery properties of silicone gaskets through careful adjustment of catalyst concentration and cure parameters. The resulting three-dimensional polymer network exhibits exceptional resistance to compression set, ensuring that gaskets maintain their sealing force throughout repeated compression and decompression cycles. This enhanced elastic memory significantly extends gasket service life while maintaining consistent sealing performance under dynamic loading conditions.

Geometric Design Optimization

Profile Configuration and Cross-Sectional Design

The geometric design of silicone gaskets plays a crucial role in determining their durability and sealing effectiveness, with optimized cross-sectional profiles distributing stress concentrations more evenly throughout the gasket structure. Advanced gasket designs incorporate features such as hollow cores, ribbed configurations, and contoured sealing surfaces that enhance flexibility while reducing the material stress under compression. These sophisticated profile geometries enable gaskets to accommodate greater surface irregularities and dimensional tolerances while maintaining effective sealing contact pressure.

Engineers utilize finite element analysis to optimize gasket cross-sectional geometry, ensuring that stress distribution remains within acceptable limits throughout the expected range of compression and operational conditions. The incorporation of stress relief features such as rounded corners, gradual transitions, and optimized wall thickness variations prevents the formation of stress concentrations that could lead to premature failure. These design refinements significantly enhance the fatigue resistance of silicone gaskets under cyclic loading conditions common in automotive and industrial applications.

Surface Texture and Contact Interface Design

The design of gasket surface textures and contact interfaces directly impacts sealing performance and durability by optimizing the contact pressure distribution and minimizing wear mechanisms. Advanced surface engineering techniques create micro-textures that enhance sealing effectiveness while reducing friction during installation and thermal cycling. These optimized surface characteristics prevent the development of leak paths while accommodating the surface finish variations commonly encountered in production hardware.

Modern gasket designs incorporate graduated surface textures that provide multiple sealing lines, creating redundant sealing barriers that maintain effectiveness even if localized wear occurs. The strategic placement of sealing ridges and contact zones ensures optimal pressure distribution while preventing over-compression that could lead to material extrusion or permanent deformation. These surface design innovations significantly extend gasket service life by minimizing wear and maintaining consistent sealing contact throughout the operational life cycle.

Environmental Resistance Engineering

Chemical Compatibility and Resistance

The long-term durability of silicone gaskets in industrial applications depends critically on their resistance to chemical attack from process fluids, cleaning agents, and atmospheric contaminants that can cause swelling, hardening, or degradation of the elastomer matrix. Advanced silicone formulations incorporate chemical resistance modifiers that provide enhanced protection against aggressive chemicals such as acids, bases, solvents, and petroleum-based fluids. These specialized additives create protective barriers within the polymer structure that prevent chemical penetration while maintaining the mechanical properties essential for effective sealing.

Manufacturers conduct extensive chemical compatibility testing to validate gasket performance in specific application environments, ensuring that material selection and design parameters are optimized for the intended service conditions. The development of application-specific silicone compounds enables gaskets to maintain their integrity when exposed to challenging chemical environments that would rapidly degrade conventional elastomeric materials. This enhanced chemical resistance significantly extends service intervals while reducing the risk of unexpected seal failures in critical applications.

Temperature Stability and Thermal Cycling Resistance

Temperature resistance represents one of the most critical design requirements for durable silicone gaskets, with advanced formulations capable of maintaining sealing effectiveness across temperature ranges from cryogenic conditions to elevated temperatures exceeding 200°C. The inherent thermal stability of silicone polymers provides exceptional resistance to thermal degradation, but design optimization is essential to minimize the effects of thermal expansion and contraction during temperature cycling. Advanced gasket designs incorporate features that accommodate differential thermal expansion between the gasket and mating hardware while maintaining effective sealing contact.

Engineers optimize gasket geometry and material properties to minimize thermal stress development during rapid temperature transitions, preventing the formation of cracks or permanent deformation that could compromise sealing integrity. The incorporation of thermal stress relief features and optimized material thickness distributions ensures that gaskets maintain their elastic properties throughout repeated thermal cycling. These design innovations enable silicone gaskets to provide reliable sealing performance in applications subject to extreme temperature variations such as automotive engines, industrial processing equipment, and aerospace systems.

Manufacturing Process Optimization

Precision Molding and Dimensional Control

The durability of silicone gaskets is significantly influenced by manufacturing process precision, with advanced molding techniques ensuring consistent dimensional accuracy and surface quality that are essential for reliable sealing performance. Modern compression molding and injection molding processes utilize computer-controlled systems that maintain precise temperature, pressure, and timing parameters throughout the cure cycle. This process control ensures uniform cross-linking and eliminates defects such as voids, inclusions, or incomplete cure that could compromise gasket durability.

Quality manufacturing processes incorporate automated inspection systems that verify dimensional accuracy, surface finish, and material properties before gaskets are approved for shipment. The implementation of statistical process control methods ensures that manufacturing variations remain within acceptable tolerances, maintaining consistent performance across production lots. These manufacturing advances enable the production of high-quality silicone gaskets that meet stringent automotive and industrial specifications while providing predictable service life characteristics.

Post-Cure Processing and Quality Assurance

Advanced post-cure processing techniques enhance the durability of silicone gaskets by optimizing the polymer structure and eliminating volatile compounds that could affect long-term performance. Controlled post-cure cycles at elevated temperatures complete the cross-linking process while driving off residual catalyst and low molecular weight compounds that could cause odor or contamination issues in sensitive applications. These post-cure processes also stabilize the mechanical properties and dimensional characteristics of gaskets, ensuring consistent performance throughout their service life.

Comprehensive quality assurance protocols validate gasket performance through accelerated aging tests, chemical compatibility evaluations, and mechanical property assessments that simulate real-world operating conditions. These testing procedures identify potential durability issues before gaskets are released for production use, ensuring that only components meeting stringent performance criteria reach end-user applications. The implementation of rigorous quality control measures significantly enhances the reliability and durability of silicone gaskets in demanding industrial environments.

Application-Specific Design Considerations

Automotive Industry Requirements

Automotive applications impose unique durability requirements on silicone gaskets due to the demanding operating conditions encountered in engine compartments, transmission systems, and environmental sealing applications. Automotive-grade silicone gaskets must withstand exposure to engine oils, coolants, fuel vapors, and exhaust gases while maintaining sealing effectiveness throughout temperature cycles ranging from sub-zero startup conditions to elevated operating temperatures. Design optimization for automotive applications focuses on enhancing oil resistance, reducing compression set, and improving retention of sealing force under dynamic loading conditions.

The automotive industry requires gaskets that maintain their performance characteristics throughout extended service intervals while meeting stringent emission control requirements. Advanced silicone gasket designs incorporate features that prevent the migration of volatile compounds that could interfere with emission control systems or sensor operation. These design considerations ensure that automotive silicone gaskets contribute to vehicle reliability while meeting increasingly stringent environmental regulations and performance standards.

Industrial Processing Applications

Industrial processing environments present unique challenges for silicone gaskets, including exposure to aggressive chemicals, steam, cleaning solutions, and repeated sterilization cycles. Industrial-grade gasket designs optimize material selection and geometric configuration to provide enhanced resistance to chemical attack while maintaining the flexibility needed for effective sealing in applications with significant thermal cycling. The incorporation of FDA-approved silicone compounds enables use in food processing and pharmaceutical applications where product purity and regulatory compliance are critical considerations.

Design optimization for industrial applications emphasizes durability under repeated cleaning and sterilization procedures that can degrade conventional elastomeric materials. Advanced silicone formulations maintain their mechanical properties and surface integrity when exposed to high-temperature steam sterilization, caustic cleaning solutions, and sanitizing compounds commonly used in industrial processing facilities. These enhanced durability characteristics reduce maintenance requirements while ensuring consistent sealing performance in critical process applications.

FAQ

What factors most significantly impact the service life of silicone gaskets in industrial applications

The service life of silicone gaskets depends primarily on material quality, environmental conditions, and installation practices. High-quality platinum-cured silicone compounds with appropriate additive packages provide superior resistance to thermal degradation, chemical attack, and compression set compared to lower-grade materials. Environmental factors such as temperature cycling, chemical exposure, and UV radiation can significantly accelerate aging, making material selection critical for specific applications. Proper installation techniques that avoid over-compression or damage during assembly also play a crucial role in maximizing gasket service life.

How do design modifications improve the performance of silicone gaskets under high-temperature conditions

Design modifications for high-temperature applications focus on optimizing material formulations and geometric configurations to minimize thermal stress and maintain sealing effectiveness. Advanced silicone compounds incorporate heat-stabilizing additives and optimized cross-linking systems that resist thermal degradation at elevated temperatures. Geometric design features such as controlled compression ratios and thermal expansion accommodation prevent excessive stress development during temperature cycling. Surface treatments and specialized cure systems further enhance high-temperature performance by improving the thermal stability of the polymer matrix.

What quality control measures ensure consistent durability in manufactured silicone gaskets

Comprehensive quality control measures include raw material testing, process parameter monitoring, and finished product validation to ensure consistent gasket durability. Incoming material inspection verifies that silicone compounds meet specified performance requirements before processing. Real-time monitoring of molding parameters such as temperature, pressure, and cure time ensures consistent processing conditions. Finished product testing includes dimensional verification, hardness measurement, and accelerated aging tests that validate long-term performance characteristics under simulated service conditions.

How does gasket geometry affect sealing performance and durability in dynamic applications

Gasket geometry significantly influences sealing performance and durability by controlling stress distribution, contact pressure, and accommodation of relative motion between sealing surfaces. Optimized cross-sectional profiles distribute compression forces more evenly, reducing stress concentrations that could lead to premature failure. Design features such as controlled wall thickness, rounded corners, and graduated sealing surfaces enhance flexibility while maintaining effective contact pressure. Dynamic applications benefit from geometric designs that accommodate relative motion while preventing extrusion or wear at the sealing interfaces.

Table of Contents

- Material Composition and Polymer Structure

- Geometric Design Optimization

- Environmental Resistance Engineering

- Manufacturing Process Optimization

- Application-Specific Design Considerations

-

FAQ

- What factors most significantly impact the service life of silicone gaskets in industrial applications

- How do design modifications improve the performance of silicone gaskets under high-temperature conditions

- What quality control measures ensure consistent durability in manufactured silicone gaskets

- How does gasket geometry affect sealing performance and durability in dynamic applications