3d silicone molds for resin

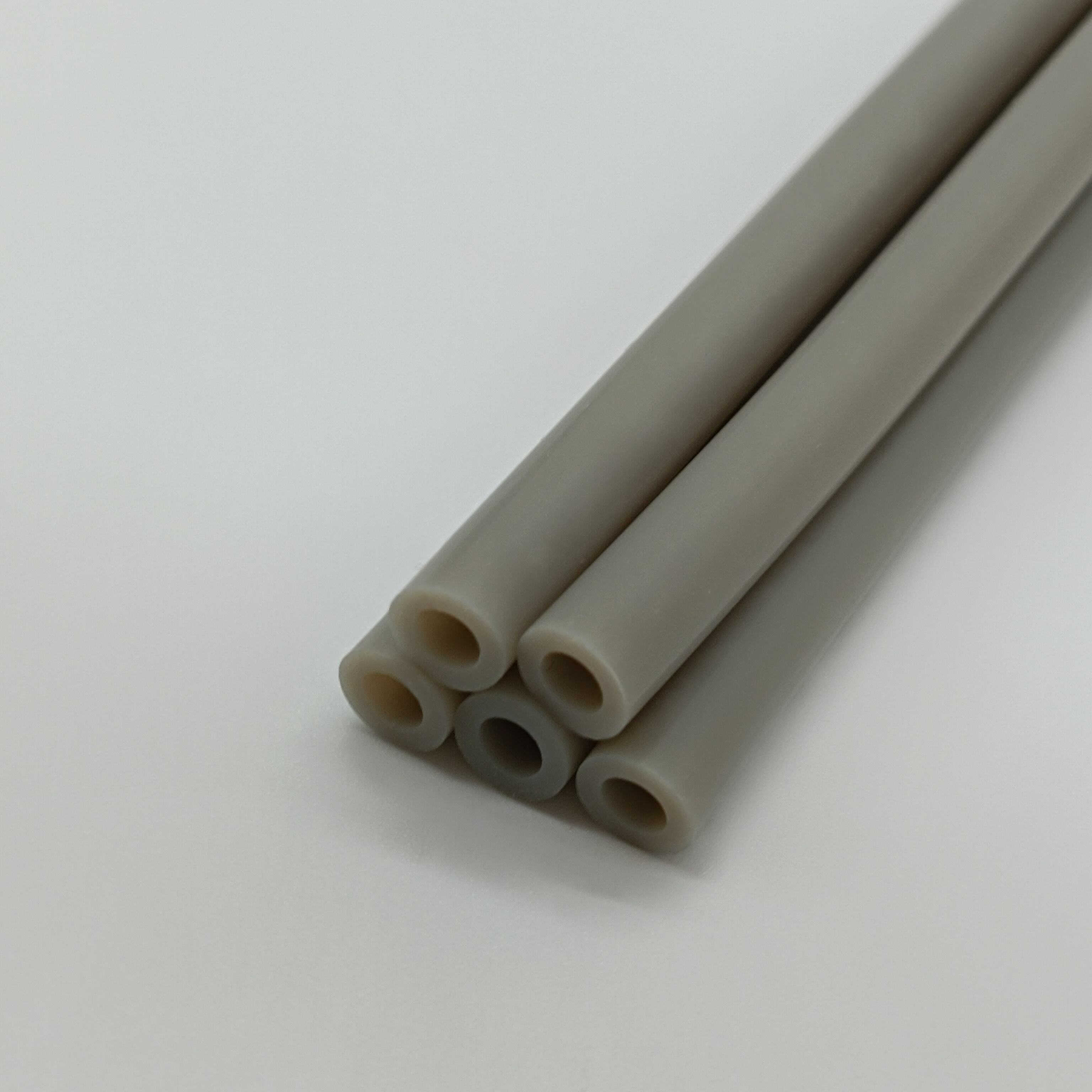

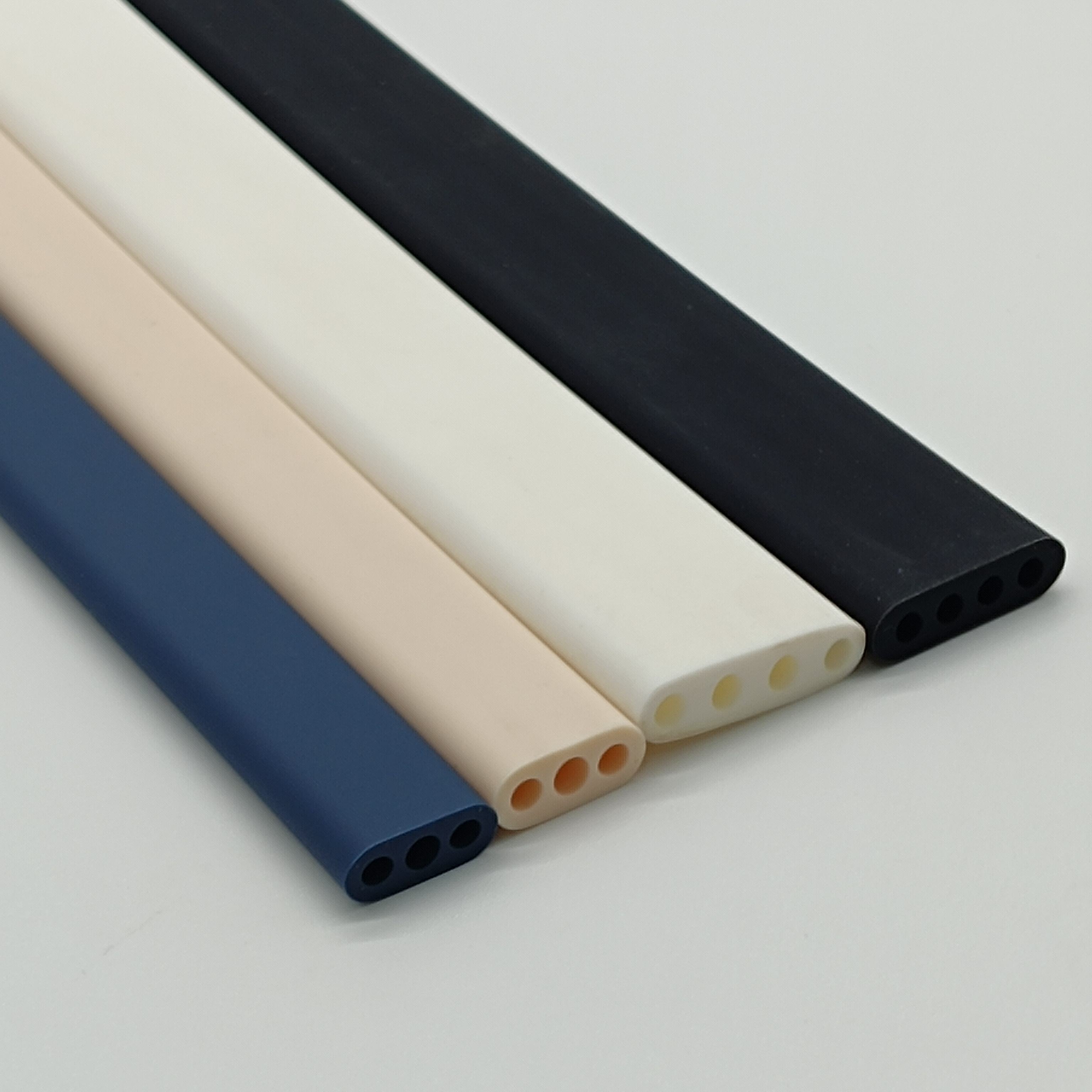

3D silicone molds for resin represent a revolutionary advancement in crafting and manufacturing, offering unparalleled precision and versatility in creating intricate resin pieces. These molds are crafted from high-quality silicone material that combines flexibility with durability, enabling the production of complex three-dimensional shapes with exceptional detail retention. The molds feature a non-stick surface that ensures easy release of finished pieces without the need for additional release agents. Their heat-resistant properties allow them to withstand varying temperatures during the curing process, making them suitable for both UV and epoxy resins. The flexible nature of silicone enables the creation of undercuts and complex geometries that would be impossible with traditional rigid molds. These molds maintain their shape and integrity through multiple uses, providing consistent results in professional and hobby applications. They are particularly valuable in jewelry making, architectural modeling, prototype development, and artistic expressions, offering creators the ability to reproduce detailed designs repeatedly with high fidelity.