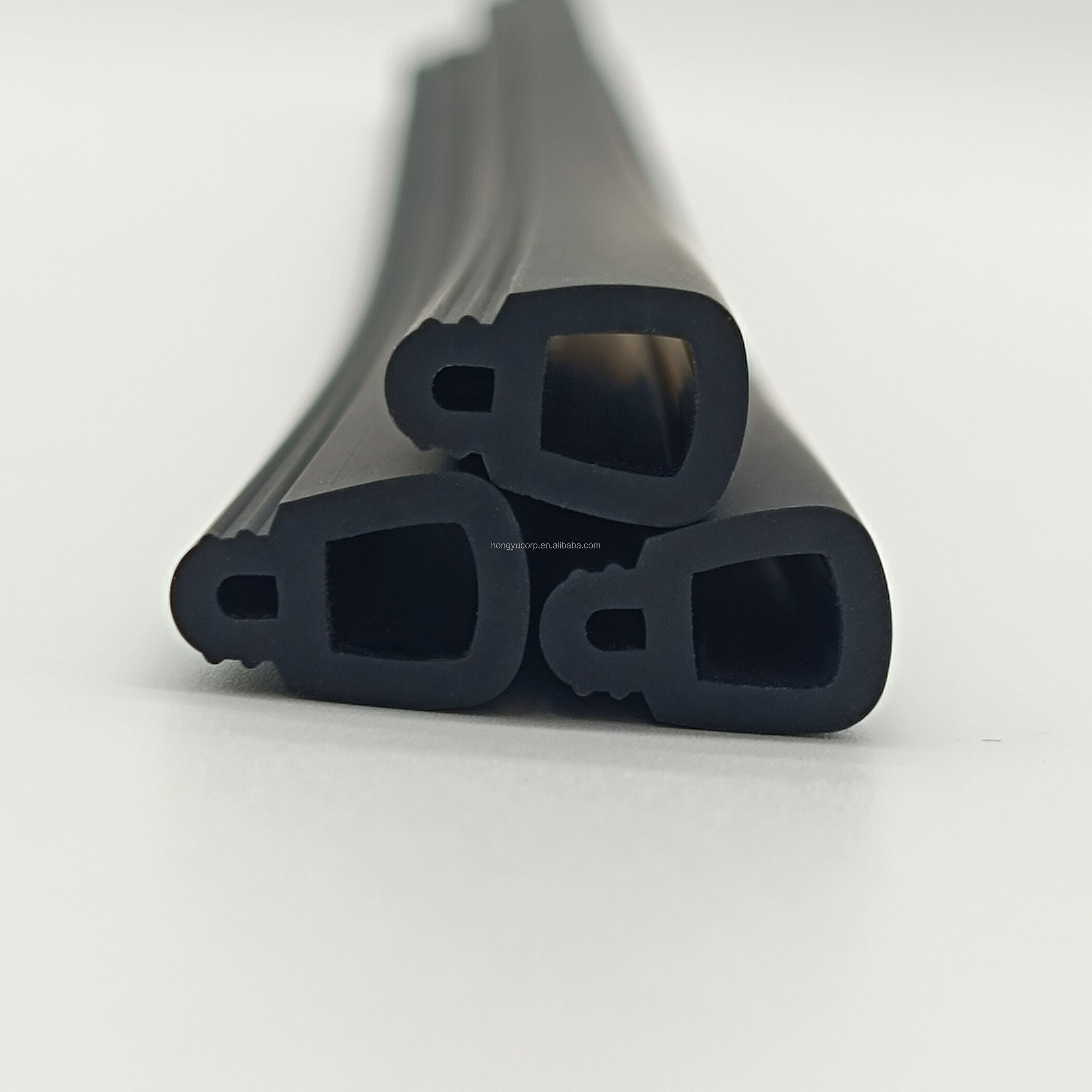

extruded silicone profiles

Extruded silicone profiles represent a cutting-edge solution in industrial and commercial applications, offering exceptional versatility and performance characteristics. These profiles are manufactured through a sophisticated extrusion process that transforms high-quality silicone compounds into precise, customizable shapes and configurations. The material composition ensures remarkable resistance to extreme temperatures, ranging from -60°C to +230°C, while maintaining its structural integrity and flexibility. These profiles serve as critical components in various industries, including automotive, construction, aerospace, and medical equipment manufacturing. The extrusion process allows for the creation of complex geometries and cross-sections, enabling designers and engineers to develop solutions that perfectly match specific application requirements. The profiles can be engineered to provide essential functions such as sealing, insulation, vibration dampening, and protection against environmental factors. Their inherent properties include excellent UV resistance, outstanding weather durability, and exceptional chemical stability, making them ideal for both indoor and outdoor applications. The manufacturing process ensures consistent quality and dimensional accuracy throughout the entire length of the profile, guaranteeing reliable performance in demanding environments.