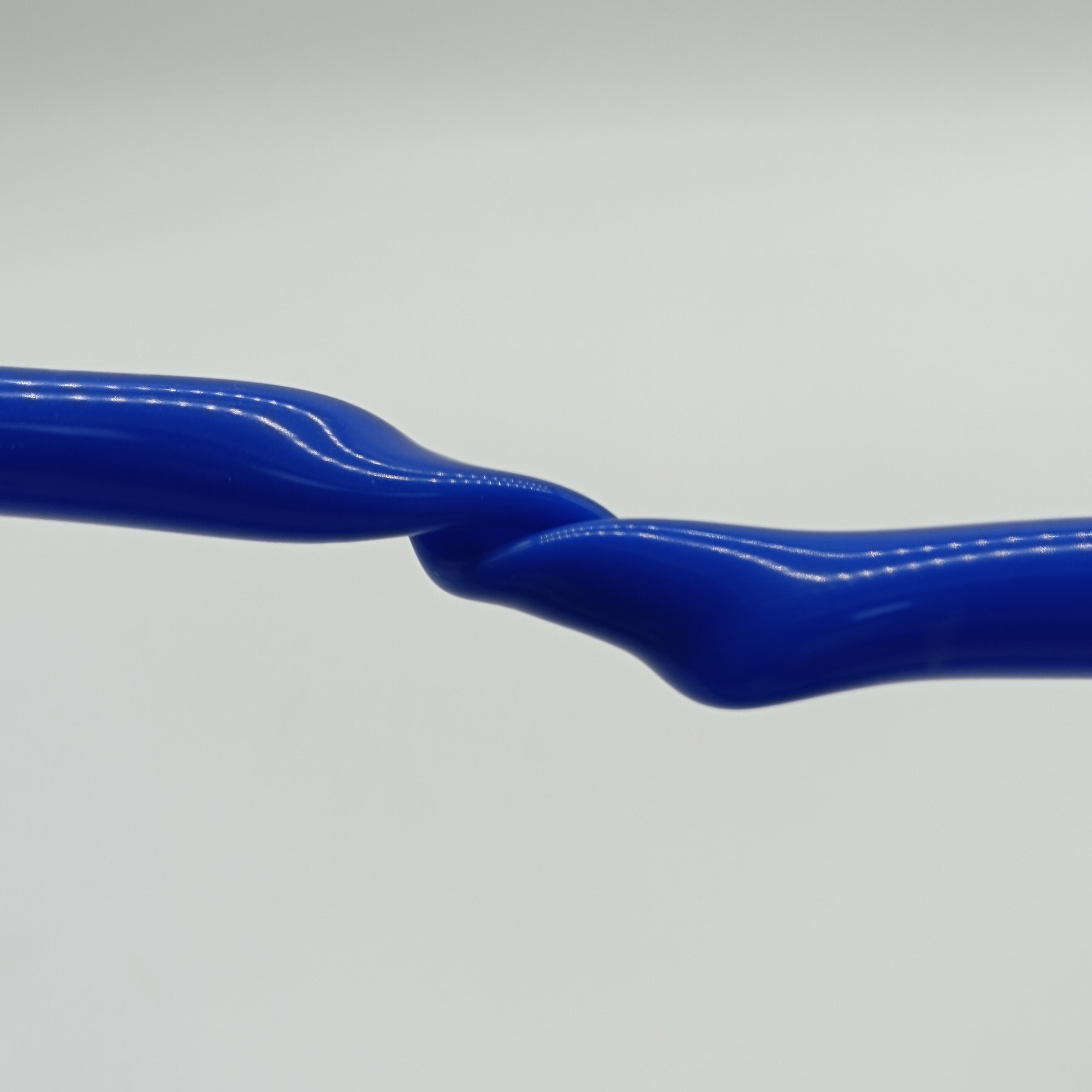

silicone extrusion profiles

Silicone extrusion profiles represent a cutting-edge manufacturing solution that combines versatility with precision engineering. These profiles are created through a sophisticated process where silicone material is forced through specially designed dies to produce continuous sections with specific cross-sectional shapes. The technology enables the production of both solid and hollow profiles with exceptional dimensional accuracy and consistency. These profiles exhibit remarkable resistance to extreme temperatures, ranging from -60°C to +200°C, while maintaining their structural integrity and flexibility. The manufacturing process allows for customization in terms of hardness, color, and specific performance characteristics to meet diverse industrial requirements. Silicone extrusion profiles find extensive applications across multiple sectors, including automotive weather sealing, medical device components, food processing equipment, and construction industry seals. The profiles can be manufactured with various surface finishes and can incorporate special features such as self-adhesive backing or reinforcement materials. Their excellent compression set resistance and weather resistance make them ideal for both indoor and outdoor applications, while their non-toxic nature ensures compliance with FDA and other regulatory standards.