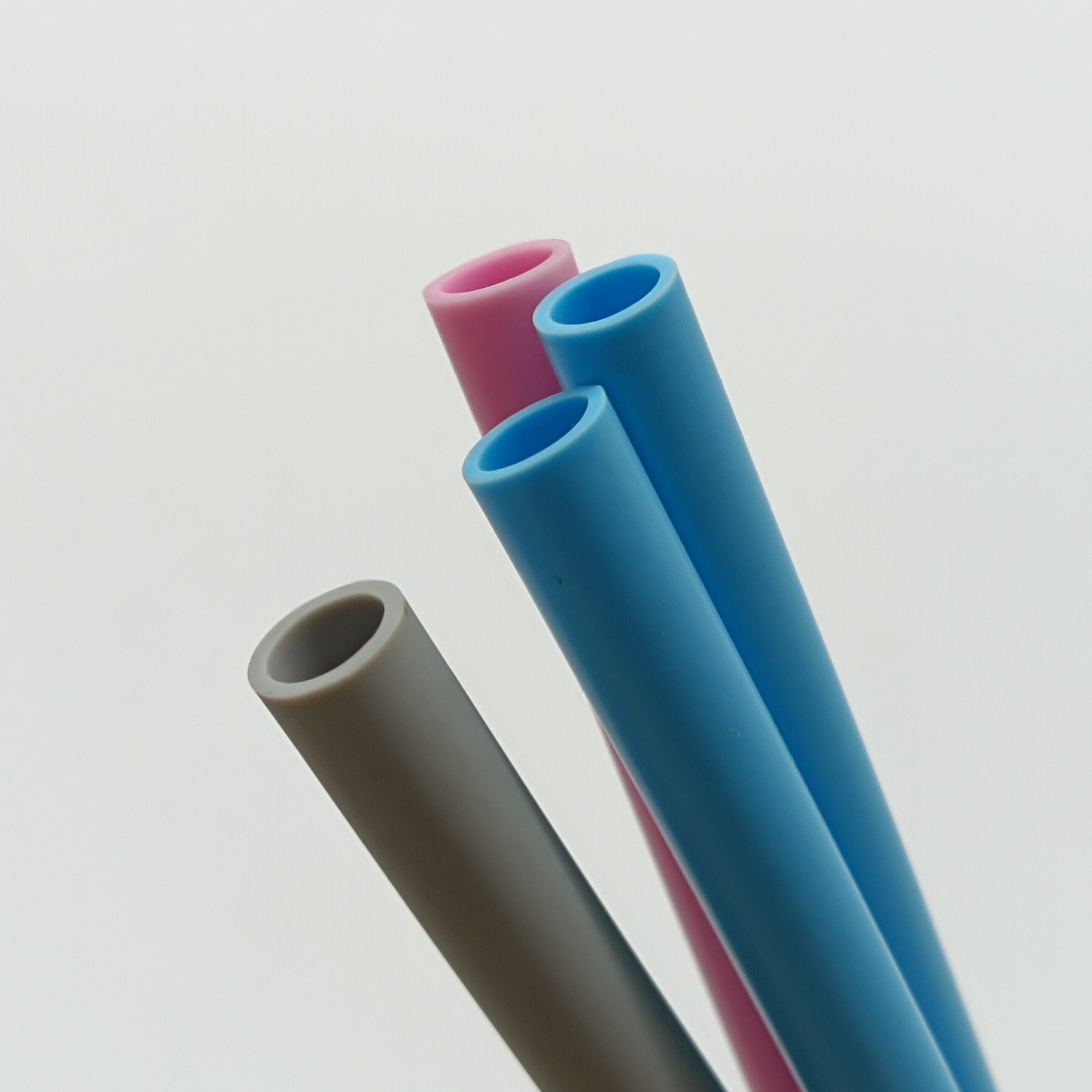

high temperature silicone extrusion

High temperature silicone extrusion represents a sophisticated manufacturing process designed to produce silicone components capable of withstanding extreme thermal conditions. This advanced technique involves forcing silicone material through a die to create profiles, tubes, cords, and other specialized shapes that maintain their integrity at temperatures ranging from -60°C to 300°C. The process utilizes specialized high temperature silicone compounds formulated with advanced cross linking agents and reinforcing fillers, ensuring superior performance in demanding environments. The extrusion equipment features precisely controlled temperature zones, advanced screw designs, and specialized die technologies that enable consistent production of high quality components. This manufacturing method excels in producing continuous lengths of silicone products with uniform cross sections, making it ideal for automotive, aerospace, medical, and industrial applications where heat resistance is crucial. The process allows for customization of material hardness, color, and specific performance characteristics while maintaining excellent dimensional stability and mechanical properties at elevated temperatures.