Superior Material Properties and Customization

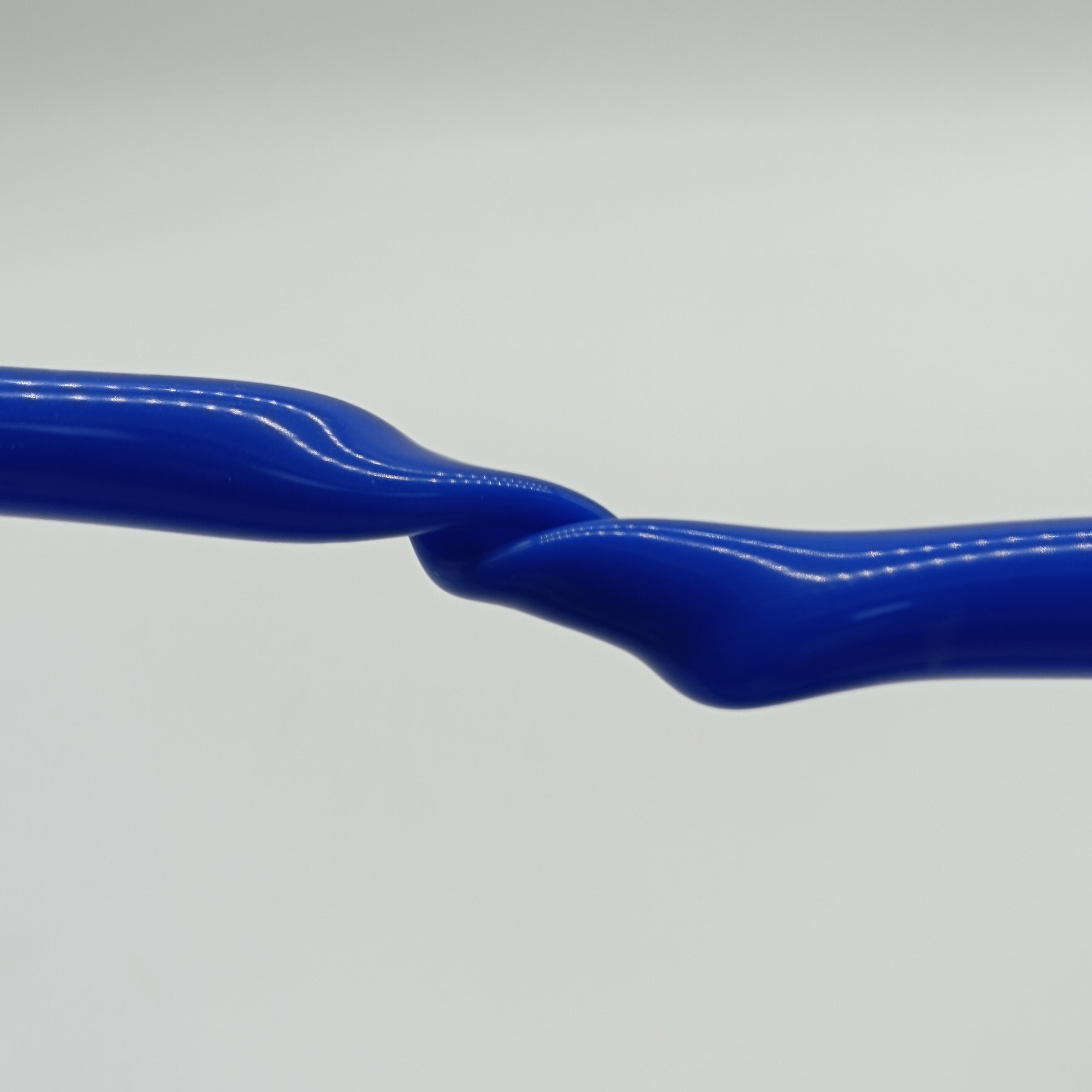

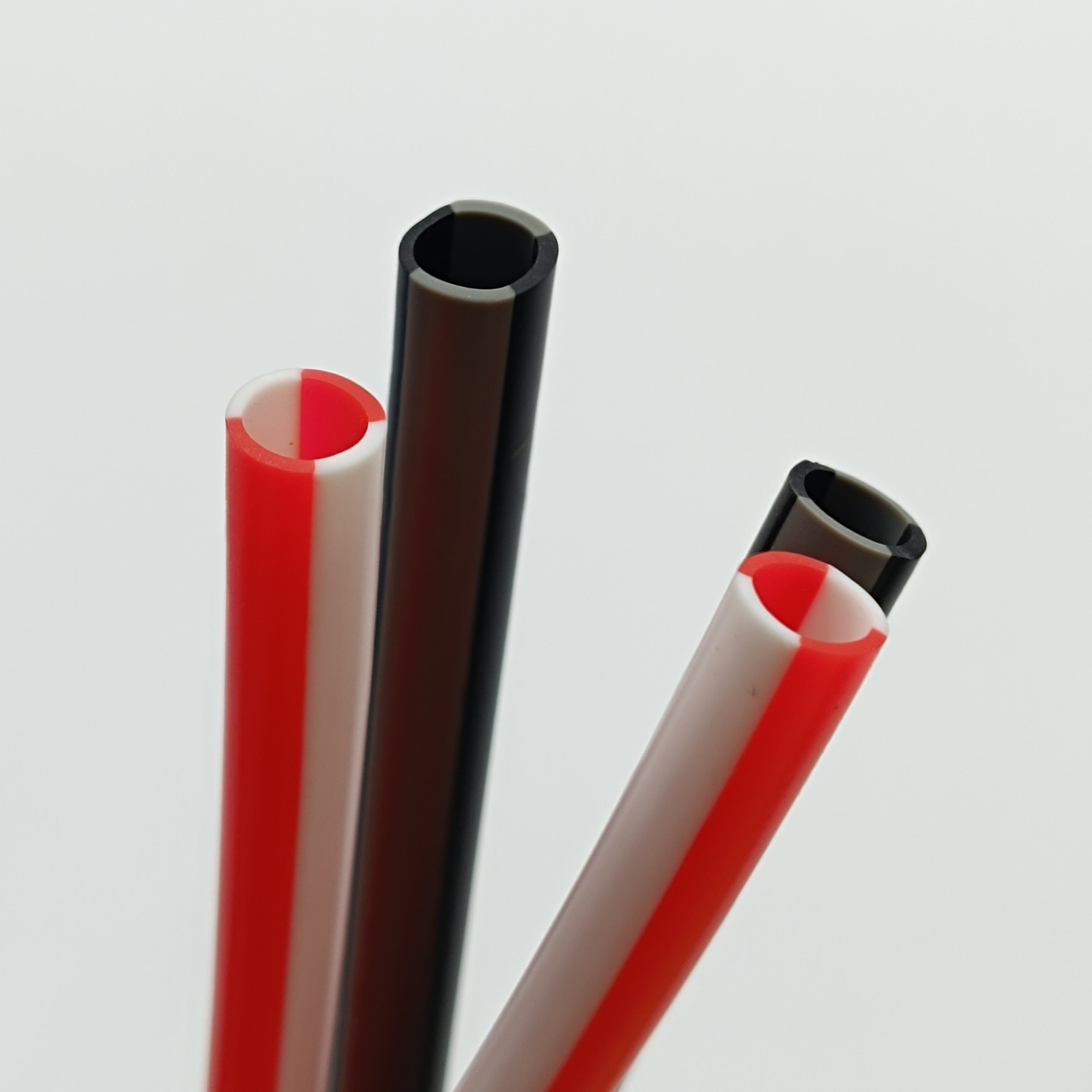

Silicone extrusion excels in delivering products with exceptional material properties that can be precisely tailored to specific applications. The process allows for fine-tuning of shore hardness, tear strength, and elongation characteristics to meet exact requirements. Manufacturers can incorporate specialized additives during the extrusion process to enhance specific properties such as flame retardancy, electrical conductivity, or thermal conductivity. The ability to control these parameters ensures that each product perfectly matches its intended use, whether it's for medical implants requiring biocompatibility or industrial seals demanding chemical resistance. This level of customization extends to physical properties, allowing for precise control of wall thickness, surface texture, and dimensional tolerances.