custom silicone extrusion

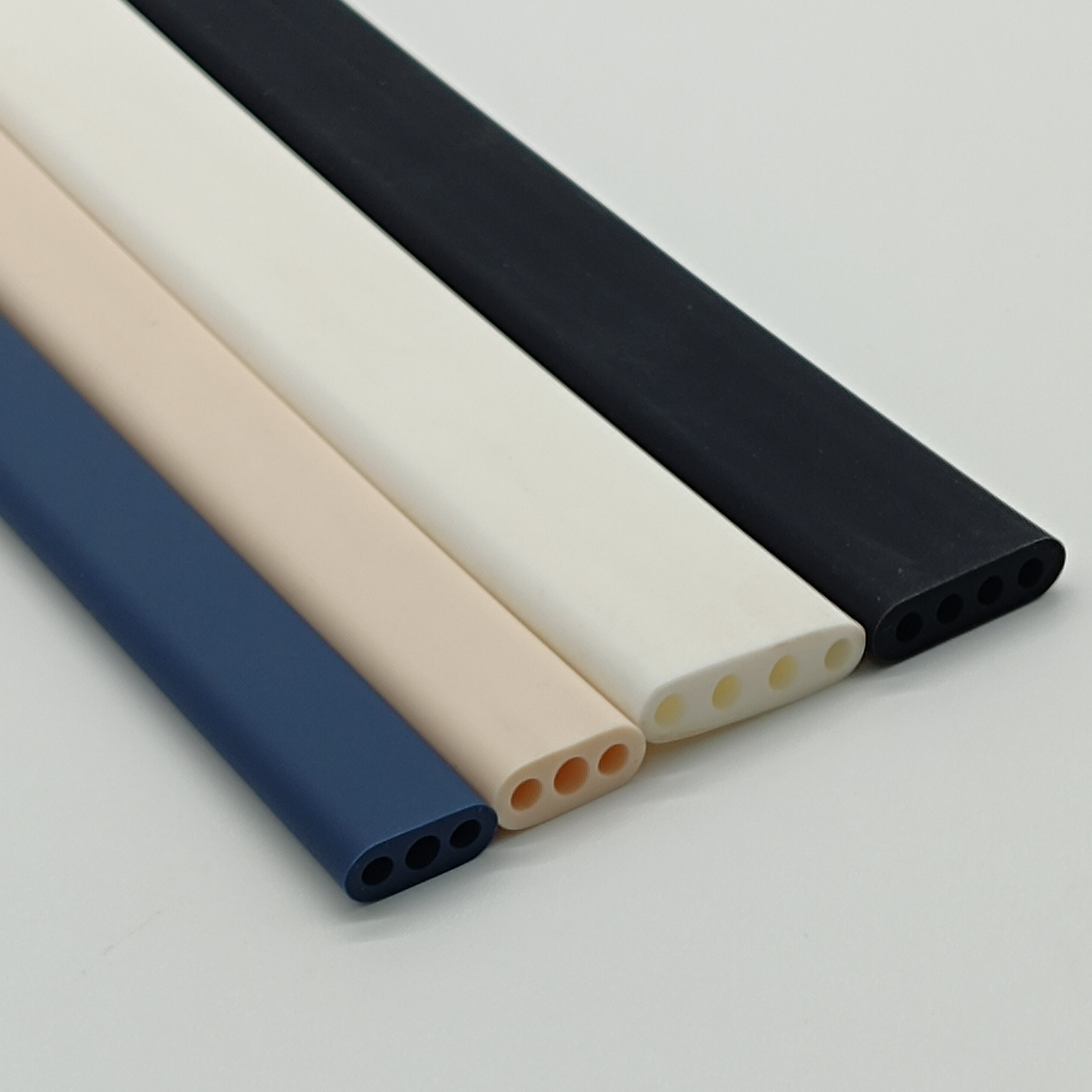

Custom silicone extrusion represents a sophisticated manufacturing process that transforms raw silicone materials into precisely engineered profiles, tubes, and components. This versatile technology employs specialized equipment that forces silicone material through custom-designed dies to create continuous lengths of products with consistent cross-sectional profiles. The process accommodates various silicone formulations, allowing manufacturers to achieve specific physical properties such as heat resistance, flexibility, and durability. Advanced temperature control systems and precision die designs ensure dimensional accuracy and surface quality throughout the production run. The technology supports both solid and hollow profiles, with capabilities for multi-lumen tubing, complex geometries, and custom color matching. Modern extrusion systems incorporate real-time monitoring and quality control measures, maintaining tight tolerances and ensuring product consistency. These systems can produce components for medical devices, automotive parts, industrial seals, and numerous other applications requiring high-performance silicone materials. The process is particularly valuable for creating long, continuous profiles with uniform properties, making it ideal for both prototype development and high-volume production runs.