silicone sponge extrusion

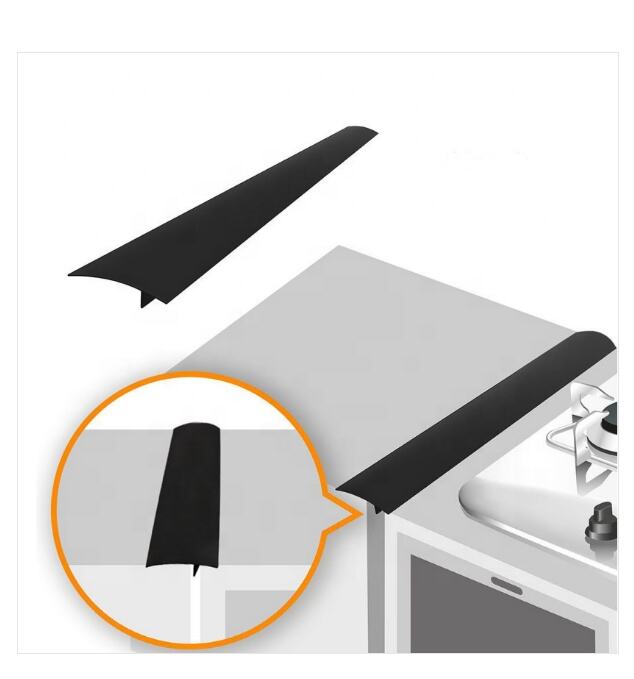

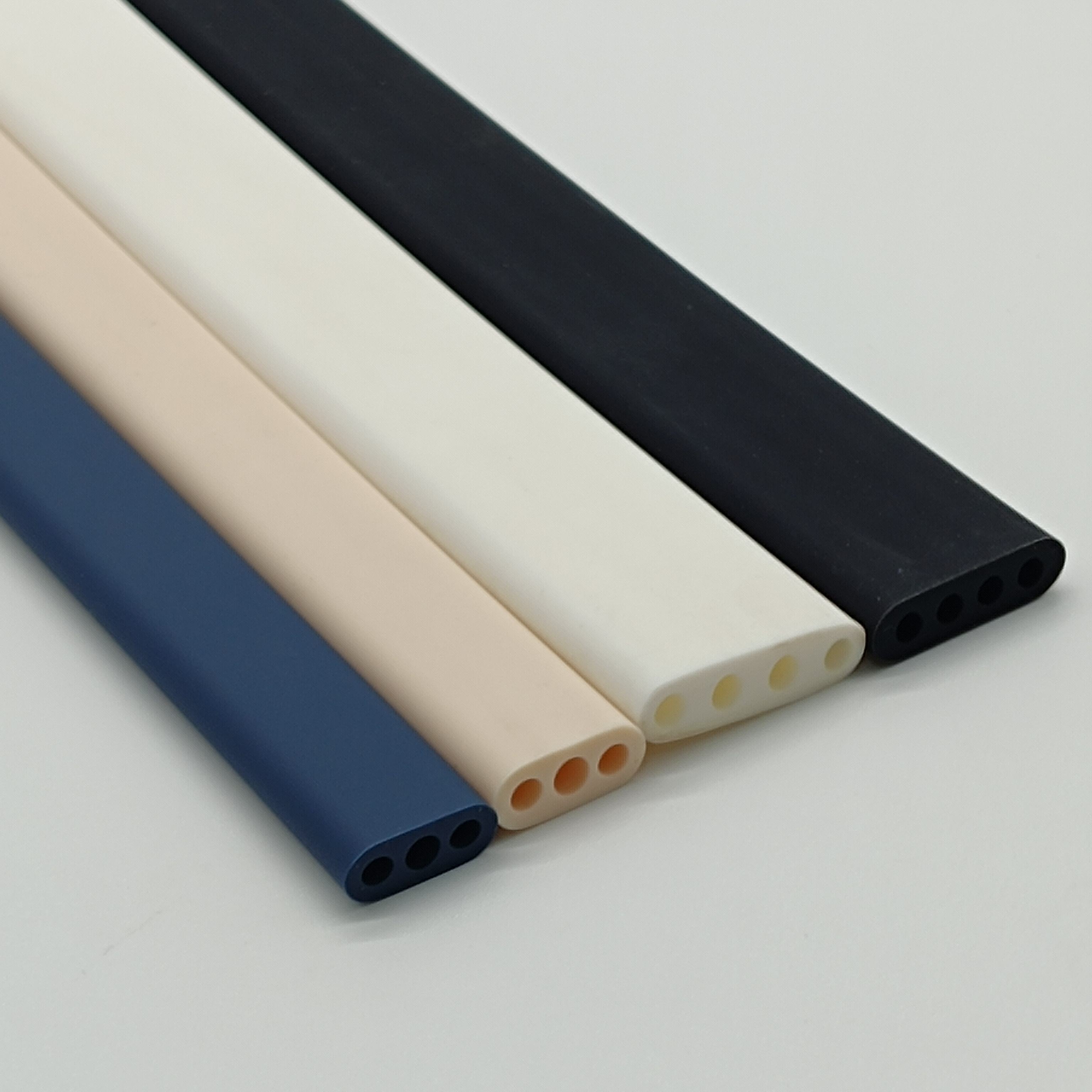

Silicone sponge extrusion represents a sophisticated manufacturing process that creates versatile, high-performance silicone foam materials through continuous extrusion technology. This advanced process combines raw silicone materials with specialized blowing agents and catalysts, passing them through precisely controlled temperature zones in an extruder to create a uniform, cellular structure. The resulting product features consistent density, excellent compression recovery, and superior environmental resistance. The process allows for precise control over the material's physical properties, including density, hardness, and cell structure, making it ideal for various industrial applications. The extrusion method enables the production of continuous lengths of silicone sponge profiles in various shapes and sizes, from simple tubes and strips to complex custom profiles. This manufacturing technique ensures optimal material distribution and uniform cell structure throughout the product, resulting in enhanced performance characteristics such as improved thermal insulation, weather resistance, and durability. The process is particularly notable for its ability to maintain tight dimensional tolerances and produce consistent quality across long production runs.