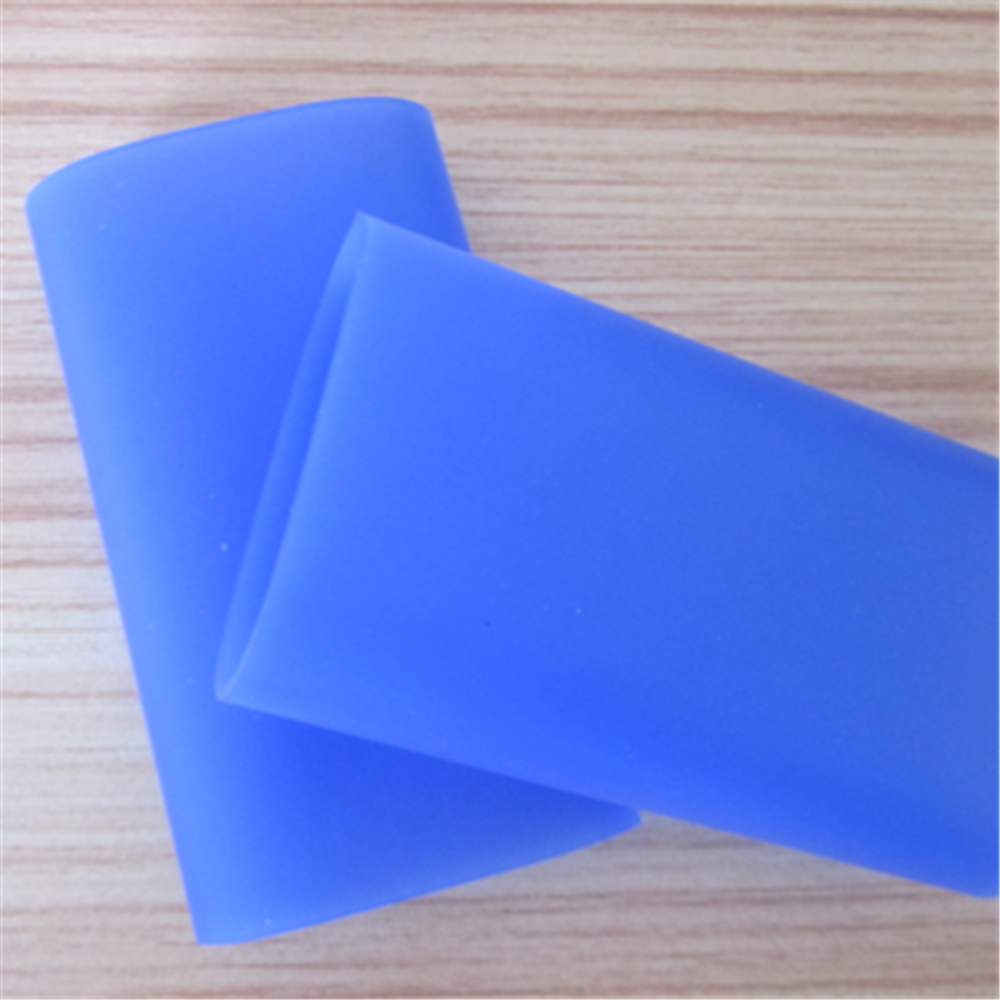

high quality silicone extrusion

High quality silicone extrusion represents a cutting-edge manufacturing process that transforms silicone materials into precisely engineered profiles, tubes, and components. This sophisticated process involves forcing silicone rubber compounds through specially designed dies under controlled temperature and pressure conditions, resulting in continuous profiles with consistent dimensions and properties. The technology incorporates advanced temperature control systems, precision die design, and automated monitoring to ensure dimensional stability and product uniformity. Modern silicone extrusion processes utilize computer-controlled equipment that maintains strict tolerances while offering flexibility in production runs. The extruded silicone products demonstrate exceptional resistance to extreme temperatures, chemical exposure, and UV radiation, making them ideal for demanding applications. The process accommodates various silicone formulations, including medical-grade, food-grade, and industrial-grade materials, each tailored to specific end-use requirements. Quality control measures, including in-line monitoring and post-production testing, ensure that every extruded component meets rigorous industry standards and customer specifications.