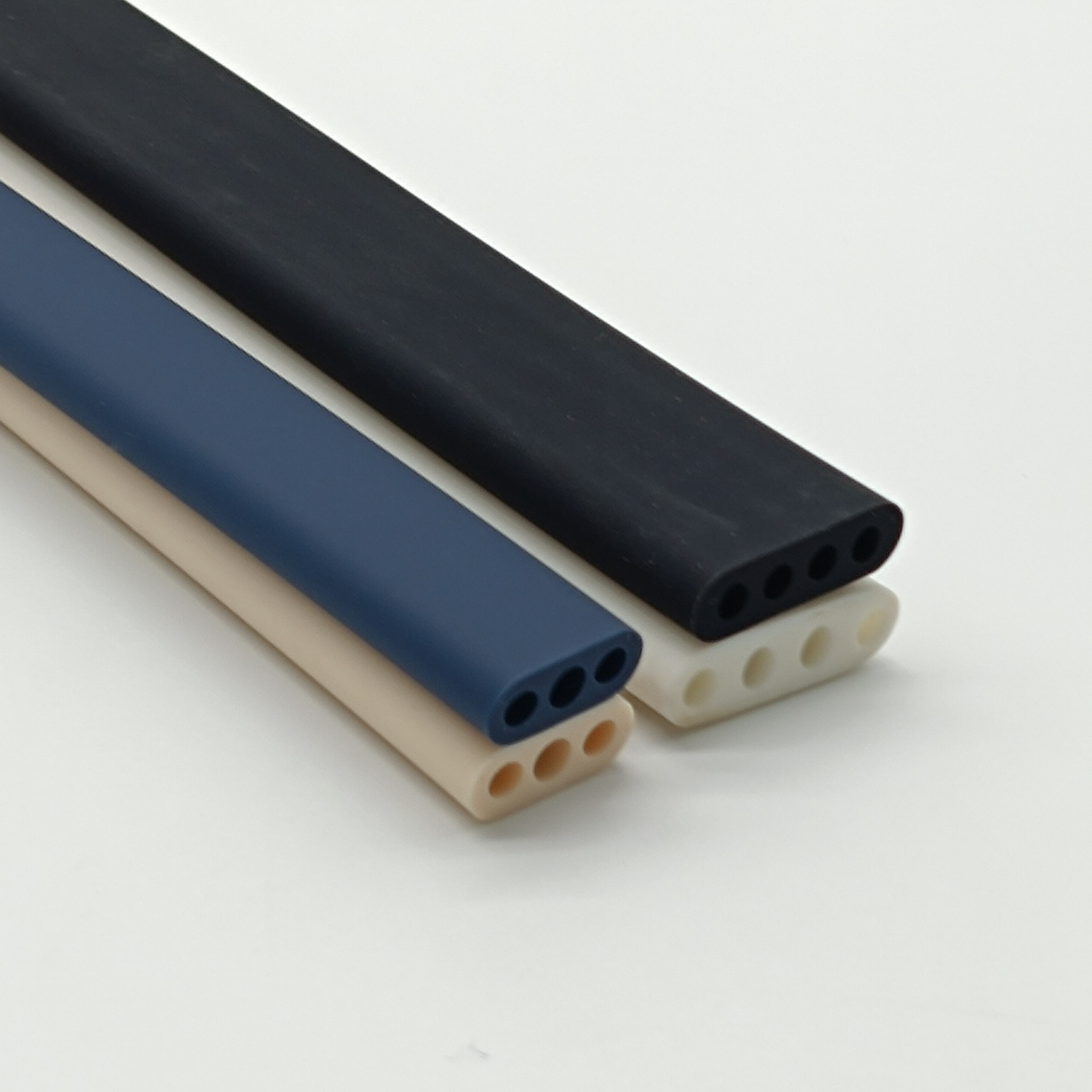

غطاء سيليكون ملون

تمثل الحلقات الملونة من السيليكون تطوراً مهماً في حلول إدارة الكابلات والحماية، حيث تجمع بين الوظيفة والجاذبية البصرية. يتم تصنيع هذه المكونات متعددة الاستخدامات من مطاط سيليكوني عالي الجودة، مما يوفر متانة عالية ومقاومة لدرجات الحرارة القصوى تتراوح بين -60°م و230°م. نظام الترميز بالألوان الفريد يسمح بتحديد سريع لأنواع مختلفة من الكابلات أو الأنظمة، مما يسهل عمليات الصيانة والتركيب. تتميز هذه الحلقات بهندسة دقيقة مع حواف ناعمة ومستديرة تمنع إتلاف الكابلات وتحافظ على توزيع مناسب للتوتر. وهي متوفرة بأحجام وتكوينات متنوعة، وتقدم خصائص إغلاق ممتازة ضد الغبار والرطوبة والعوامل البيئية الأخرى. يتضمن تكوين المادة مقاومة طويلة الأمد للمرونة ومقاومتها للأشعة فوق البنفسجية، مما يمنع التدهور حتى في الاستخدامات الخارجية. تم تصميمها بحيث تتضمن تصنيفات صلابة شور محددة تحافظ على قبضة مثالية مع إمكانية التركيب والإزالة بسهولة عند الحاجة. وميزة الترميز بالألوان مدمجة داخل تركيب المادة نفسها، وليس مجرد طلاء سطحي، مما يضمن قدرة دائمة على التعرف على الهوية طوال عمر المنتج.